- HOME

- Metal 3D Printing

Metal 3D Printing

What is Metal 3d printing?

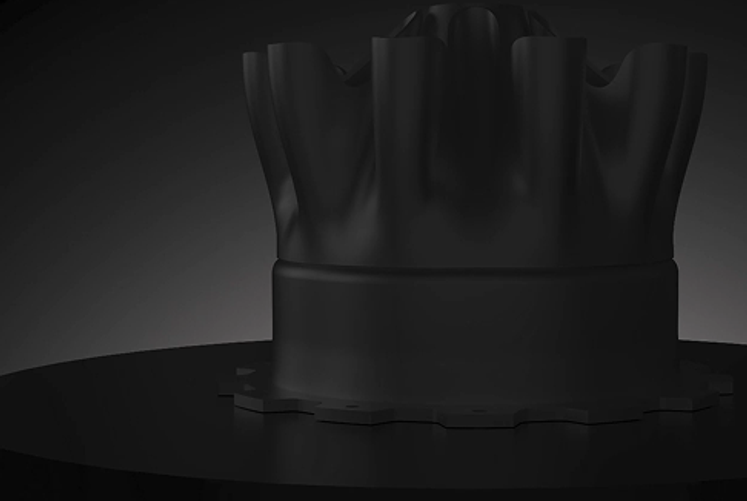

Metal 3D Printing is a cutting-edge additive manufacturing technology that builds fully dense metal parts directly from digital designs. Using high-precision lasers to selectively melt fine metal powders layer by layer, it enables unparalleled design freedom, exceptional detail, and performance-grade strength.

3D printing service process

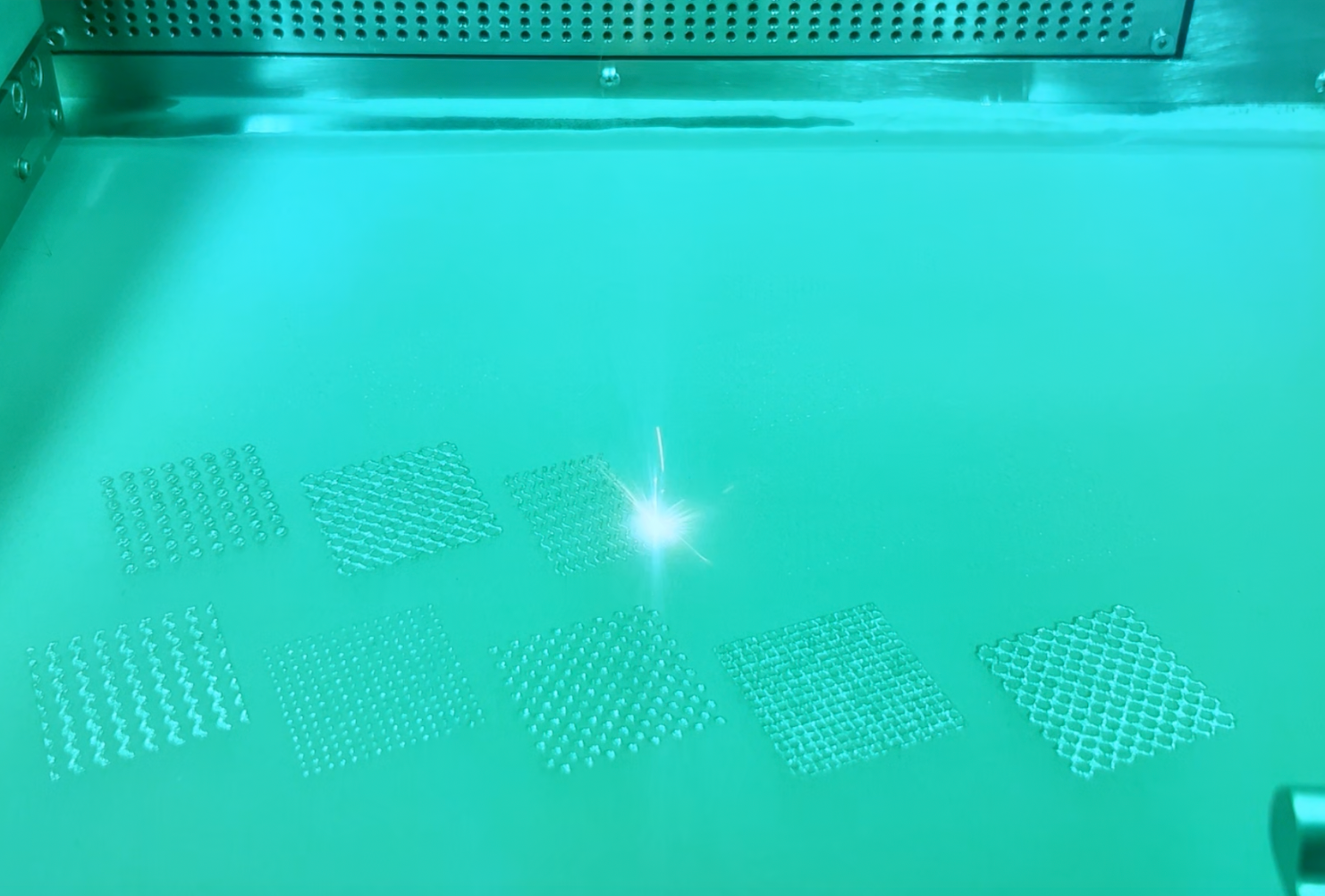

Our R&D team is dedicated to improving printing accuracy and production efficiency through precise laser parameter control, temperature management, and material parameter adjustments.

Consultation & Quotation

- Discuss project

- Upload files

- Select material

- Get quote

Metal 3D Printing

- File check

- Provide printing suggestions

- Start printing

Post Processing

- Remove support

- Polish & sandblasting

- Painting

Quality Control

- Surface inspection

- Dimension islection

- Mechanical testing

Delivery

- Pack & ship

- QC certificate & shipping list

- Global shipping available

Materials that we have

Our R&D team is dedicated to improving printing accuracy and production efficiency through precise laser parameter control, temperature management, and material parameter adjustments.

- Superalloy

- Aluminum Alloy

- Cobalt-Chromium Alloy

- Titanium Alloy

- Alloy Steel

- Copper Alloy

- Customize Alloy

High Temperature Alloy

Superalloy powder is designed for extreme environments, offering exceptional strength, oxidation resistance, and thermal stability. Ideal for aerospace, energy, and high-performance engineering, it enables the production of complex components that perform under high temperatures and stress.

| Main Products | AISi10Mg | High strength aluminum |

| Main Particle Size Range | 0-25μm 15-53μm 45-105μm 53-150μm | |

| Flowability | ≤20s/50g | |

| Bulk Density | ≥4.20g/cm³ | |

| Oxygen Content | ≤200ppm | |

| Nitrogen Content | ≤200ppm | |

| Mechanical Properties | 330±20 260±20 8±2 | 580±50 530±50 10±2 |

Aluminum Alloy

Aluminum alloy powder is lightweight yet strong, offering excellent thermal conductivity, corrosion resistance, and high strength-to-weight ratio. It is ideal for automotive, aerospace, and lightweight structural parts where performance and weight reduction are critical.

| Main Products | GH4169 | GH3536 | GH3625 |

| Main Particle Size Range | 0-25um,15-53um,45-105um,53-150μm, | ||

| Flowability | ≤20s/50g | ||

| Bulk Density | ≥4.20g/cm2 | ||

| Oxygen Content | ≤200ppm | ≤250ppm | ≤200ppm |

| Nitrogen Content | ≤200ppm | ≤200ppm | ≤150ppm |

| Mechanical Properties Tensile Strength/MPa Yield Strength/MPa Elongation/% | 1400±50 MPa 1100±20 MPa 20±5 % | 710±30 MPa 310±20 MPa 40±5% | 920±30 MPa 550±20 MPa 42±5 % |

Cobalt-Chromium Alloy

Cobalt-Chromium alloy powder is known for its exceptional biocompatibility, wear resistance, and high-temperature strength. It is widely used in dental, orthopedic, and aerospace applications where durability and corrosion resistance are essential.

| Main Products | CoCrW |

| Main Particle Size Range | 0-25μm 15-53μm 45-105μm 53-150μm |

| Flowability | ≤25s/50g |

| Bulk Density | ≥4.20g/cm³ |

| Oxygen Content | ≤600ppm |

| Nitrogen Content | ≤300ppm |

| Mechanical Properties | 1000±50 600±50 10±2 |

Titanium Alloy

Titanium alloy powder offers an exceptional combination of high strength, low weight, and excellent biocompatibility. It is the preferred choice for dental, medical implants, aerospace, and high-performance industrial applications.

| Main Products | GH4099 | TC4 | TA15 |

| Main Particle Size Range | 0-25μm 15-53μm 45-105μm 53-150μm | ||

| Flowability | ≤15s/50g | 35s/50g | |

| Bulk Density | ≥4.20g/cm³ | 2.30g/cm³ | |

| Oxygen Content | ≤200ppm | ≤1000ppm | ≤1200ppm |

| Nitrogen Content | ≤150ppm | ≤300ppm | ≤300ppm |

| Mechanical Properties Tensile Strength/MPa Yield Strength/MPa Elongation/% | 1200±50 920±30 25±5 | 1100±50 900±20 10±2 | 1050±30 940±20 12±5 |

Alloy Steel

Alloy steel powder is designed for high-performance applications, offering excellent strength, hardness, and wear resistance. It is widely used in tooling, automotive, and aerospace industries for manufacturing durable, high-precision parts.

| Main Products | 18Ni300 | 420 | 12Cr9Ni |

| Main Particle Size Range | 0-25μm 15-53μm 45-105μm 53-150μm | ||

| Flowability | ≤25s/50g | 23s/50g | |

| Bulk Density | ≥4.00g/cm³ | 3.80g/cm³ | |

| Oxygen Content | ≤300ppm | ||

| Nitrogen Content | ≤200ppm | ≤300ppm | |

| Mechanical Properties Tensile Strength/MPa Yield Strength/MPa Elongation/% | 2050±50 1950±50 5±2 | 1750±50 1450±50 6±2 | 1800±30 1700±20 10±2 |

Customize Alloy

Customized alloy powder is developed based on specific client requirements, combining multiple metals to achieve precise material properties. From strength and corrosion resistance to thermal performance, we work closely with clients in aerospace, automotive, and medical sectors to create tailored powders that enhance product performance.

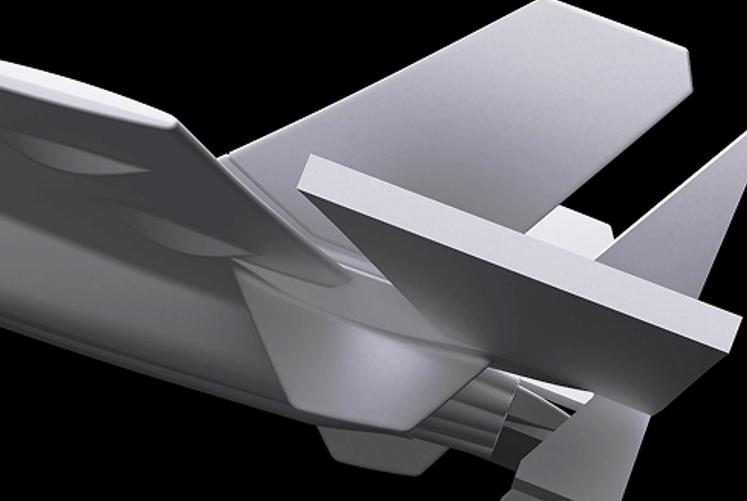

Benefits of Metal 3D Printing

High Precision

Metal parts are produced with ±0.05mm dimensional accuracy and fine surface finish, fully meeting the stringent standards of aerospace, medical, and tooling applications.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Fast Turnaround

A streamlined production workflow—from file submission to shipment—enables rapid lead times and worldwide delivery, supporting fast iteration and time-critical projects.

Material Versatility

Multiple metal powders are available, including titanium, stainless steel, and cobalt-chromium, allowing engineers to meet performance requirements across demanding industries.

DfAM Engineering Support

Designs are optimized for additive manufacturing by our expert team—minimizing weight, enhancing thermal flow, and unlocking the full potential of complex geometries.

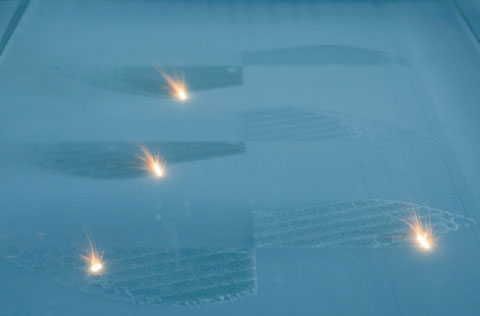

Videos showing our printing

Experience the power of metal 3D printing through real production videos—precision, speed, and innovation in every layer.

Are you looking for the right metal 3D printing equipment?