Your Trusted Partner in Metal Additive Manufacturing

Integrate R&D, manufacturing and services to create a full-process metal additive manufacturing platform.

LINMU3D

Since 2001

Suzhou Linmu Additive Technology Co., Ltd. is a high-tech enterprise focusing on metal additive manufacturing technology. It was established in 2024 and is a wholly-owned subsidiary of Tianhong Laser Co., Ltd. The company is committed to the research and development, manufacturing and application promotion of metal 3D printing equipment, which is widely used in aerospace, automobile, medical, scientific research and other fields.

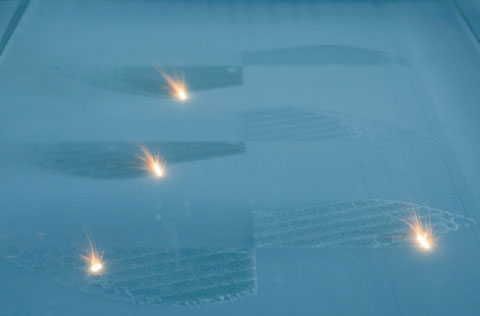

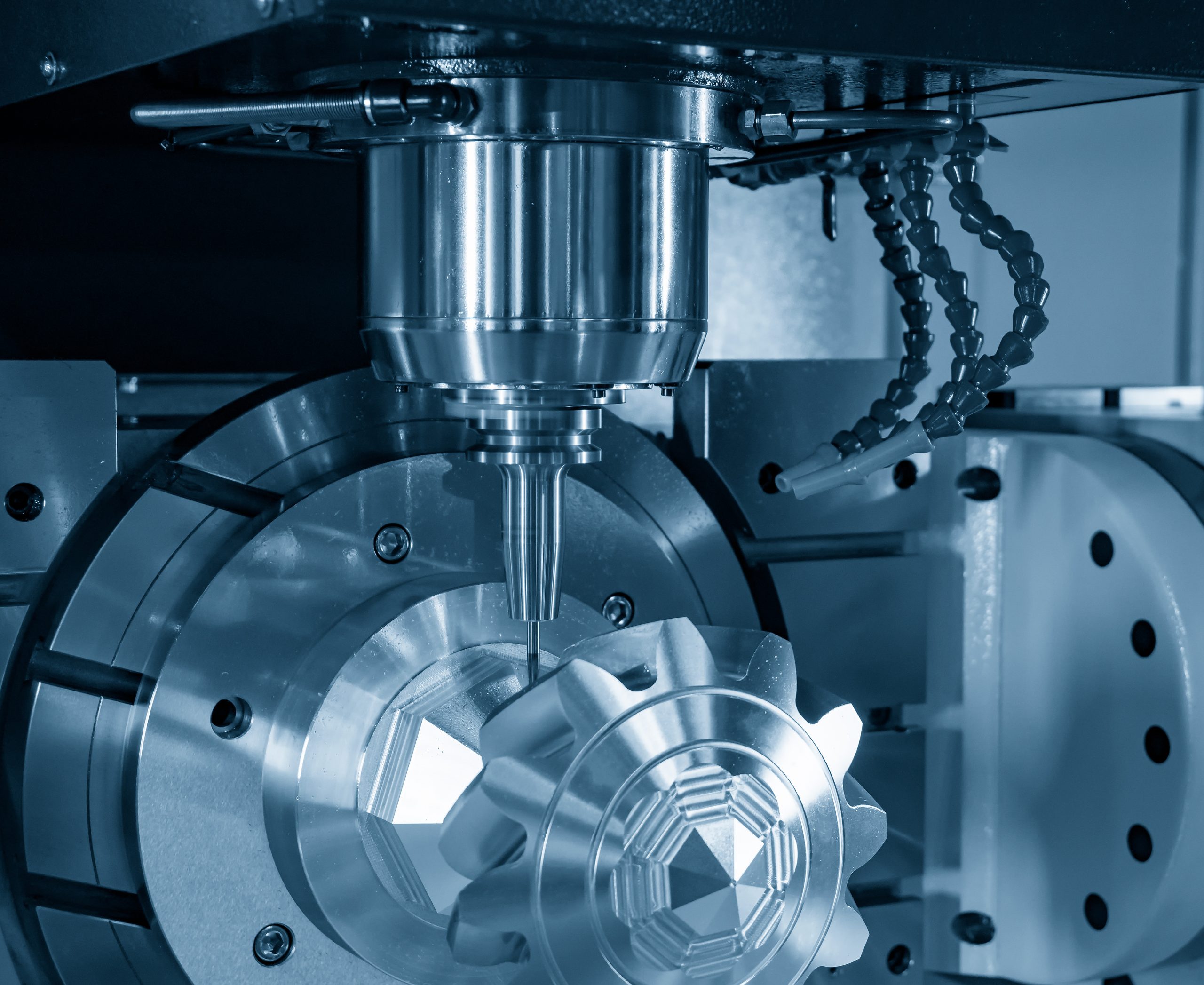

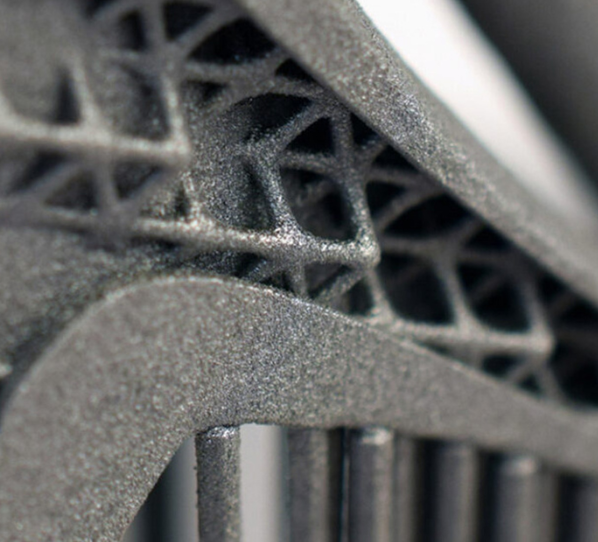

We develop and manufacture high-performance metal 3D printers based on selective laser melting (SLM) technology. Our product range covers compact desktop models to large-format industrial systems, meeting the needs of dental, aerospace, tooling, and research sectors.

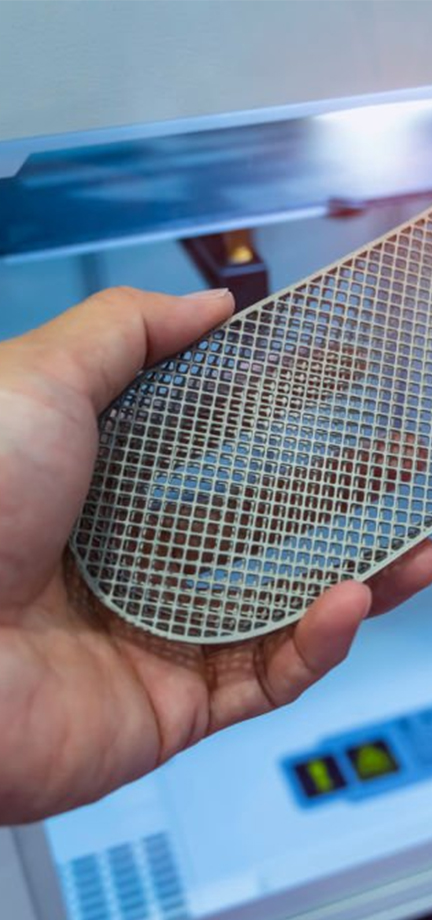

LIMU3D offer on-demand metal 3D printing services with fast turnaround, high precision, and a wide range of materials. Ideal for prototyping, low-volume production, and custom parts in aerospace, dental, and industrial applications.

We provide rapid and reliable metal 3D printing for functional prototypes. Accelerate your product development with high-precision parts that allow for quick testing, validation, and design iteration.

LIMU3D provide comprehensive training and technical support to help customers operate equipment efficiently and optimize printing results. From installation to advanced applications, we’re with you every step of the way.

We offer a wide range of high-quality metal powders including titanium, cobalt-chromium, stainless steel, aluminum, copper, and customized alloys. Our powders are optimized for additive manufacturing with excellent flowability, purity, and consistency.

Facing Global,

looking at widely

industry

To enhance its presence in metal 3D printing, the company established Suzhou Linmu3D Additive, a subsidiary dedicated to high-performance metal 3D printing equipment and process innovation

Total Area of Production Sites

National standards and industry

standards that we participated

Technology related patents and

software copyrights

Percentage of Revenue Invested in R&D

company development

2001

Suzhou Linmu3D Co., Ltd. was established. As the parent company of Suzhou Linmu3D3D, it has been deeply engaged in industrial laser technology R&D, laying a solid technological and industrial foundation for Linmu3D3D’s future development.

2011

Initiated additive manufacturing technology research and development projects in collaboration with Soochow University and other institutions, laying the foundation for technological innovation.

2019

Participated in the national key R&D project “Laser Composite Additive Manufacturing for Repair and Remanufacturing Technology and Equipment”, working jointly with universities, research institutes, and enterprises.

2020

Invested 18 million RMB to establish a subsidiary, officially entering the new energy lithium battery industry and expanding into diversified application fields.

2023

Successfully listed in the “Additive Manufacturing Typical Application Scenarios” by the Ministry of Industry and Information Technology.

Officially launched TH-M150, TH-M280, and TH-M400 mid-sized metal 3D printing equipment, upgrading the product line.

2024

Xi’an Linmu3D Co., Ltd. was established, focusing on advanced metal 3D printing technology research and industrialization.

The “ Linmu3D3D” sub-brand was officially launched, taking over Linmu3D’s global metal additive manufacturing business.

In the same year, the large-format TH-M800 printer was released, and the development of compact dental 3D printing equipment was initiated.

Started developing small-size dental equipment and officially launched the TH-M800 large-format 3D printing system, catering to broader application needs.

2025

Officially released medical dental equipment, continuing expansion into the high-end manufacturing market.

We implement export equipment and treatment service throughout the countries

well-prespected customers

Better for people and planet

You don’t need to choose between speed, quality, design and protecting the planet. Together we can build a better future for the construction industry and the environment.