- HOME

- Training & Support

Training & Support

Master the technology.

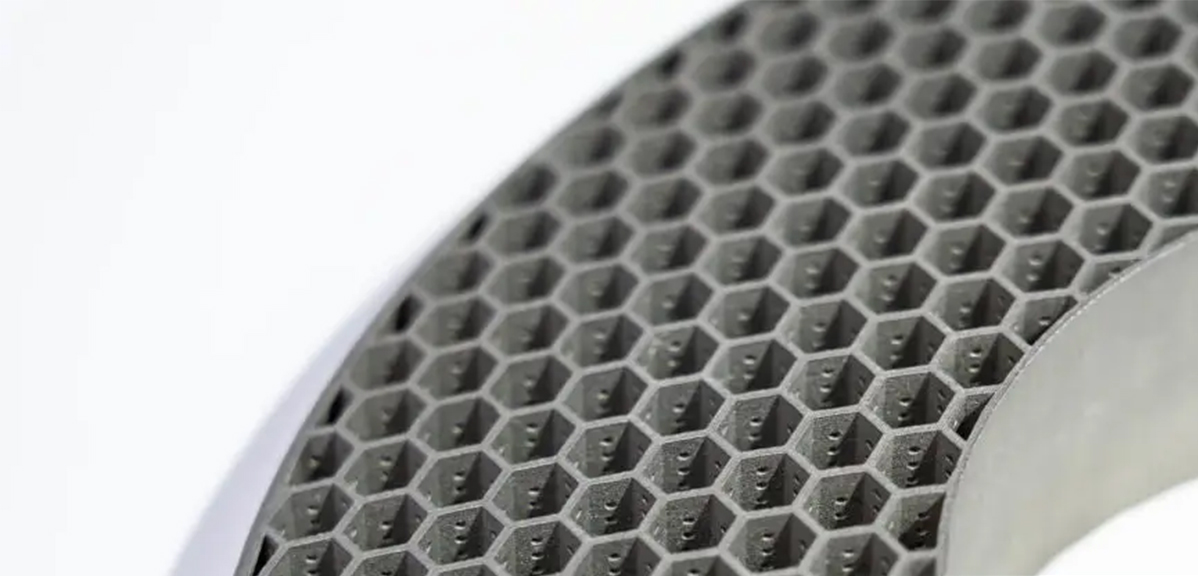

Bring your metal parts to life with professional 3D printing services.

Process tRaining

Machine Operation & maintenance

- Start-up / shutdown procedures

- Cleaning and preventive maintenance

- Nitrogen gas system & filter replacement

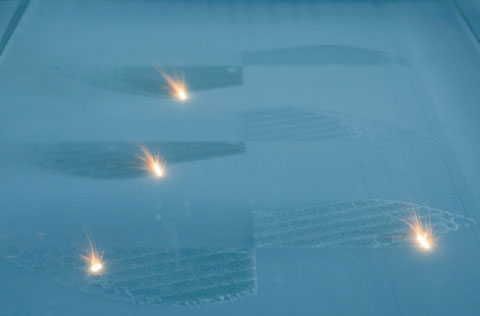

Process Parameters & Optimization

- Laser power & scan strategy setup

- Support design and deformation control

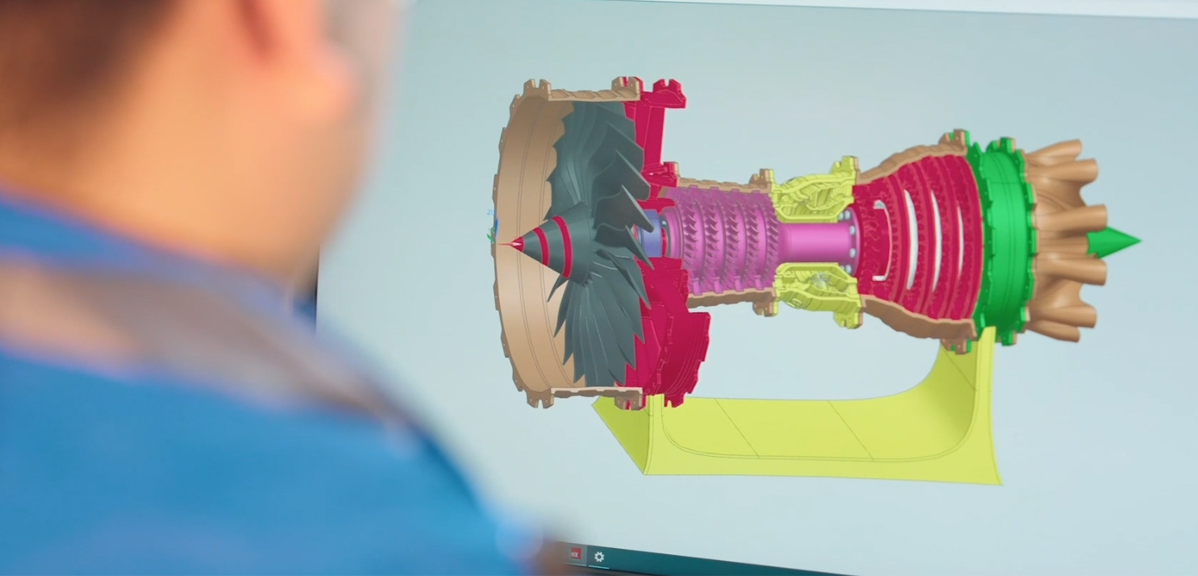

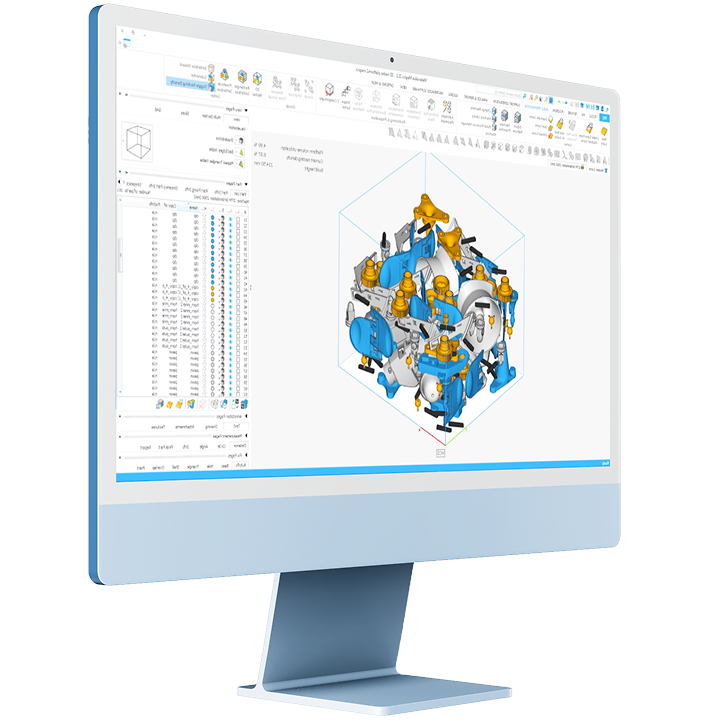

Data Preparation & Slicing Software

- Software training (e.g., Magics, Materialise)

- Import, support generation, slicing setup

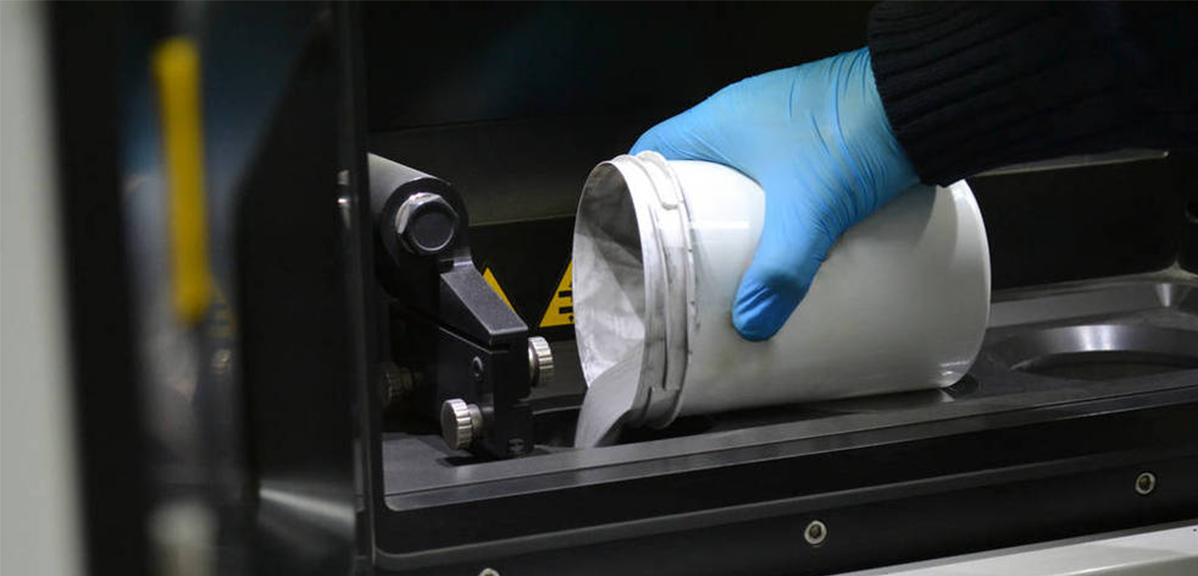

Powder Handling & Safety

- Powder sieving & recycling

- Storage environment and safety protocols

Post-Processing & Quality Control

- Support removal, heat treatment

- Surface finishing, dimensional inspection

Data Preparation & Slicing Software training

- Get up to speed with slicing software and workflow essentials

- Assistance with accurate 3D model loading and orientation

- Optimized support structure setup for metal printing

- Fine-tuning of printing parameters for quality and efficien

Process tRaining

We offers full training solutions for customers and employees, combining theory and hands-on practice to quickly master metal 3D printing operations and optimize results.

Online Training

Video tutorials, live courses

Offline Training

On-site equipment operation, face-to-face guidance

One-on-one Coaching

Customized training by engineers

Seminars & Sharing

Engaging with Industry Experts

ON-SITE

Technical Support

Technical Support

EXPAND

CLOSE

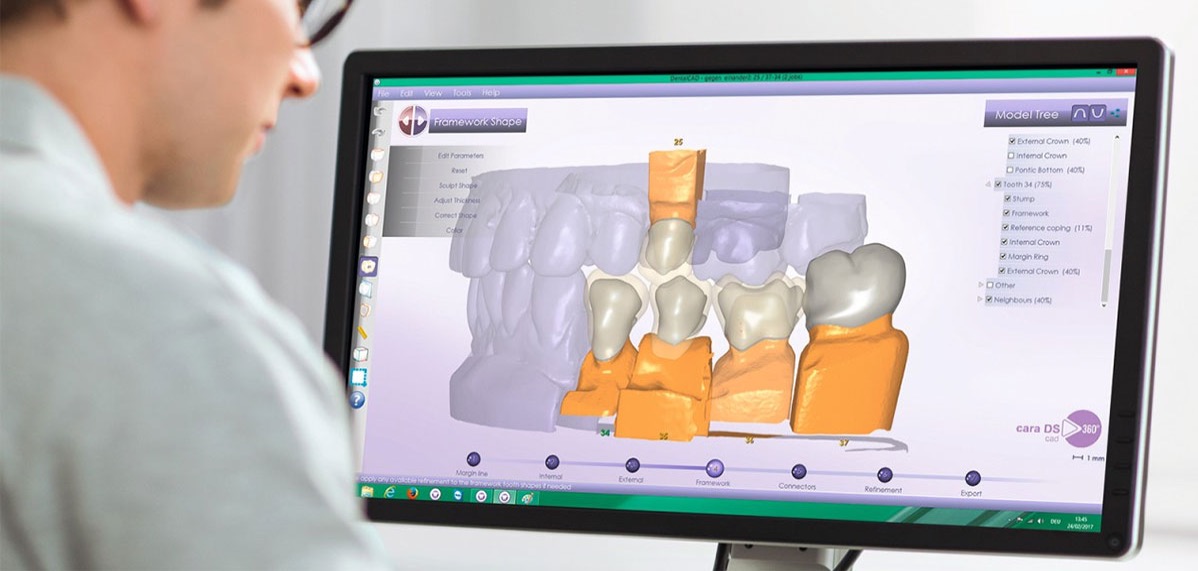

Fundamentals of Metal Additive Manufacturing & Applications

- Understand core concepts and SLM technology

- Know common materials: titanium alloy, stainless steel, cobalt-chromium

- Explore key applications: dental, medical, aerospace

Safety & Operational Guidelines

- Follow safety measures for laser radiation and high-temperature environments

- Follow laser, heat, and powder safety protocols

- Use inert gases correctly and handle emergencies

- Ensure safety for both personnel and equipment

Software & Equipment Training

- Operate slicing software and set key print parameters

- Design support structures and monitor prints in real-time

- Set up, calibrate, and troubleshoot equipment

Remote

Technical Support

Technical Support

EXPAND

CLOSE

Online Diagnosis and Troubleshooting

- Real-time monitoring of equipment status through remote connection

- Guiding customers to troubleshoot via video, voice, or screen sharing

- Providing detailed diagnostic reportss

Software and Parameter Setting Support

- Remote assistance in setting printing parameters

- Optimizing print paths and support structures

- Pushing software updates via cloud platform

Training and Demonstrations

- Offering operational demonstrations through online videos or live broadcasts

- Regularly organizing online seminars and new feature introductions

training Courses

We provide several training levels, choose one flexibility based on what you can able to.

Printing Services