Our R&D team is dedicated to improving printing accuracy and production efficiency through precise laser parameter control,

temperature management, and material parameter adjustments.

Understanding of product concept, functional requirements, and performance targets to define the development direction.

Submission of STL, STEP, PDF files, or hand-drawn sketches. Basic design inputs are acceptable at this stage.

Design is reviewed for printability. Suggestions provided for structural optimization and material selection based on application needs.

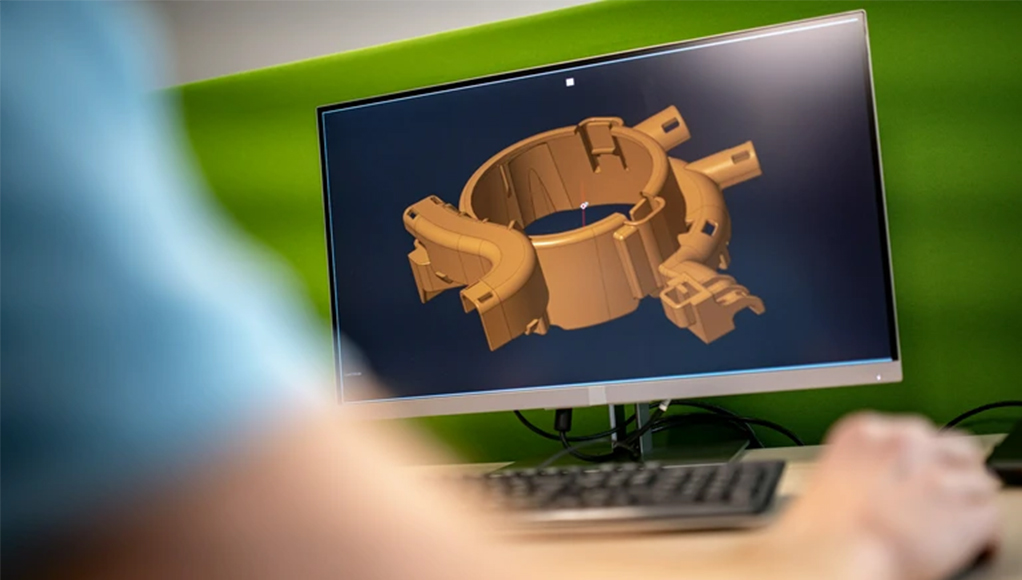

High-precision metal prototypes are produced using industrial SLM 3D printing, ensuring fast turnaround and fine detail.

Dimensional checks and visual inspection are performed. Photos, measurement data, or videos are shared for client review and approval.

Design refinements or parameter adjustments carried out based on feedback. Additional print iterations if required.

10+ years of metal 3D printing experience, one-to-one service from the engineering team

Free structural printability evaluation

A variety of alloy materials are available to meet different strength/biocompatibility requirements

Samples can be produced in as fast as 48 hours

Are you looking for the right metal 3D printing equipment?

Linmu3D Limited 2025