Our engineers will help select the best-fit solution based on your part complexity, material, and production needs.

We provide professional equipment installation services to ensure your metal 3D printer is smoothly integrated into production. Our engineers offer customized installation based on equipment model, environmental requirements, and customer needs, ensuring optimal performance.

Equipment delivery & transportation

On-site preparation

Equipment installation & commissioning

Training & operation guidance

Installation acceptance & feedback

We provides regular software updates for all equipment, ensuring you have access to the latest features, performance optimizations, and security fixes. Timely updates help you operate equipment more efficiently, improve print quality, and reduce the likelihood of faults. Each update enhances user experience, offering more convenience and performance optimization.

Continuously improve functionality with new print strategies, optimized support generation, and advanced scanning path algorithms.

Ensure seamless operation with updates for system compatibility, hardware integration, and performance improvements.

Receive timely security patches to protect your data and prevent unauthorized access to your equipment.

We provides a full range of spare parts and accessories, regularly replacing consumables and replenishing necessary parts to extend equipment life span and improve print quality and efficiency.

Commonly used for coating, cleaning, or material transfer applications. It offers excellent wear resistance, flexibility, and chemical resistance.

φ150×300 mm, used for primary filtration to remove large particles, and helps protect downstream equipment or finer filters from clogging.

Installed beneath the base plate of the forming chamber, and provides an inert gas seal to prevent oxygen ingress.

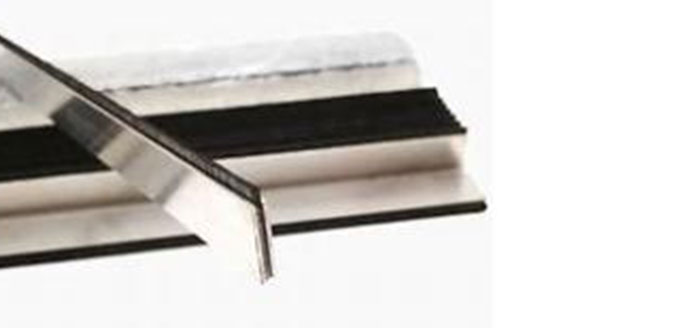

Installed around the cabinet to fill gaps and prevent dust leakage.

Used for the printer cabinet door, and prevents air, dust, and contaminants from entering or escaping

Are you looking for the right metal 3D printing equipment?

Linmu3D Limited 2025