| Features | |

| Dimensions: | 6584x3780x4200 mm3 |

| layering thickness: | 20-120 μm |

| Max Speed: | 210 cm³/h (six lasers) |

Powder cleaning bin

Molding area

Warning three-color light

Operation display screen

Up to 807×607×900 mm build size—ideal for aerospace, automotive, and mold manufacturing. Reduces splicing and post-processing costs.

Supports 4/6/8 lasers for faster builds and full-area coverage—perfect for high-efficiency, industrial-scale production.

High-precision scraper with adaptive leveling and anti-collision design ensures consistent powder laying and printing stability.

Lorem Ipsum Dolor Sit Amet, Consectetur Adipisicing Elit. Sed Do Eiusmod Tempor Incididunt Ut Labore Et Dolore Magna Aliqua. Ut Enim Ad Minim Veniam, Quis Nostrud Exercitation Ullamco Laboris

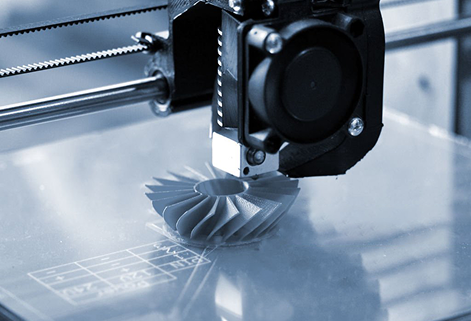

Explore applications for 3D printing across a range of industries

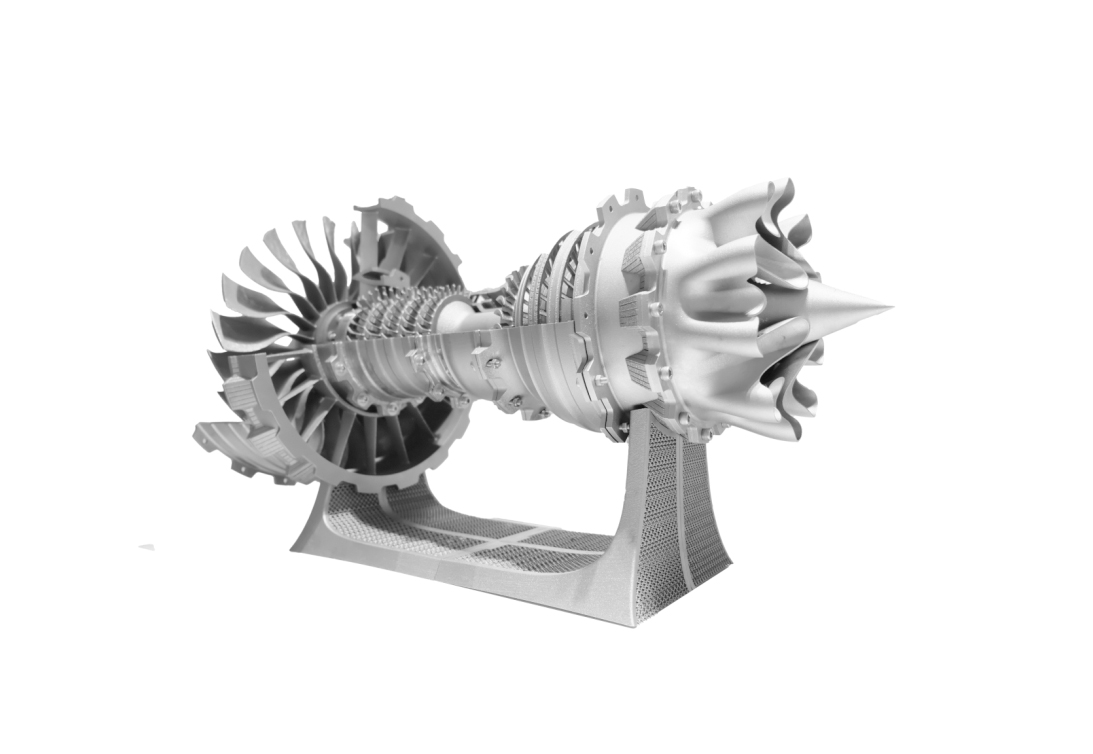

Material:TC4

Weight:3KG

Application:Aerospace

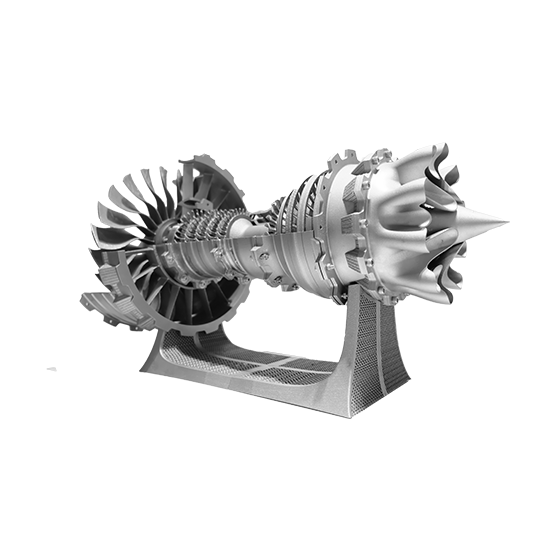

Material:316L

Weight:28KG

Application:Aerospace

| Dimension | 6584x3780x4200 mm³ (Length, Width, Height) |

| Build volume | 807 x 607 x900 mm |

| Scanning Speed | 6×7 m/s |

| Light Spot Diameter | 70μm-120μm |

| Light source | 500Wx4x6x8 |

| Powder Layering Thickness | 20μm-120μm |

| Forming Speed | Max 210 cm3/h (six lasers) |

| Applicable Material | Titanium alloys, high-temperature alloys, Aluminum Alloy,stainless steel,high-strength steel,die steel,etc. |

| Chamber Oxygen Level | ≤100ppm |

| Electrical Consumption | 380V, 34 KW |

| Protective Gas | Nitrogen/Argon |

| Data Format | STL or other Convertible File |

| Complementary software | TH-3Dprint |

| Weight | 15T |

Metal 3D Printing is a cutting-edge additive manufacturing technology that builds fully dense metal parts directly from digital designs. Using high-precision lasers to selectively melt fine metal powders layer by layer, it enables unparalleled design freedom, exceptional detail, and performance-grade strength.

Our R&D team is dedicated to improving printing accuracy and production efficiency through precise laser parameter control,

temperature management, and material parameter adjustments

Our engineers will help select the best-fit solution based on your part complexity, material, and production needs.

807×607×900 mm build size with 4/6/8 laser options. High efficiency and precision for aerospace, molds, and automotive parts.

286×286×450 mm build size with single or dual-laser options. Supports titanium, aluminum, nickel alloys, and more—perfect for aerospace and tooling applications.

Small-format design for rapid prototyping with industrial-grade metals. Supports one-button printing and remote control—ideal for research and product development.

406×206×230 mm build area with 20 μm resolution. Captures fine sole textures and logos. Optimized powder system for stable shoe mold production.

Linmu3D Limited 2025