- HOME

- Consumer Electronics

Consumer Electronics

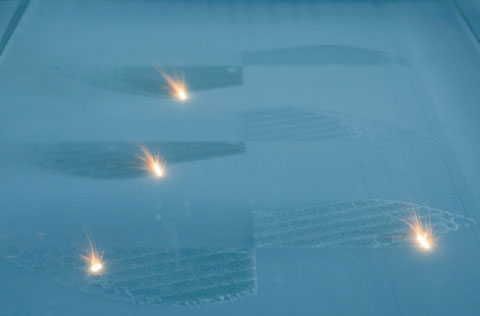

High-speed metal 3D printing for mass production

Metal 3D printing is reshaping the design and manufacturing of consumer electronics. It enables brands to achieve structural innovation, lightweight design, and product customization, accelerating time-to-market and enhancing competitiveness.

What we doing

High-Precision Printing for Micro & Complex Parts

Enables micron-level accuracy for intricate structures like fine brackets, micro-holes, and complex geometries in electronic components.

Excellent Surface Finish

High-energy laser and optimized parameters deliver smoother surfaces, reducing post-processing effort and cost.

Fast Prototyping from Design to Part

Accelerates the transition from CAD to real parts, speeding up design verification and iteration.

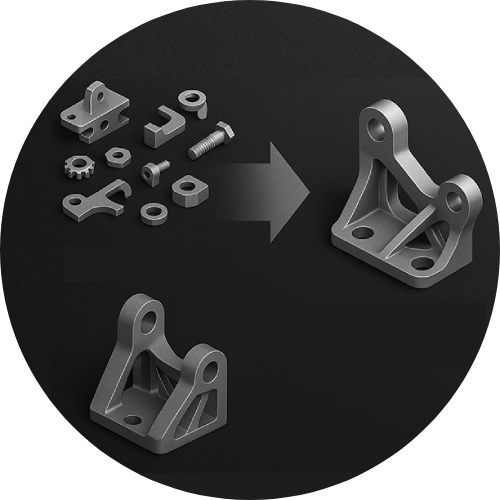

Integrated Structural Design

Reduces component count through single-build integration, achieving lightweight and robust design.

Compatible with Multiple Metal Materials

Supports stainless steel, titanium, and aluminum alloys to meet various functional and application needs.

customer success stories

In the metal 3D printing process, the core of process development is to optimize each step to ensure the quality and performance of the final product

这里是机器2的描述文本

这里是机器3的描述文本

Printing Showcase

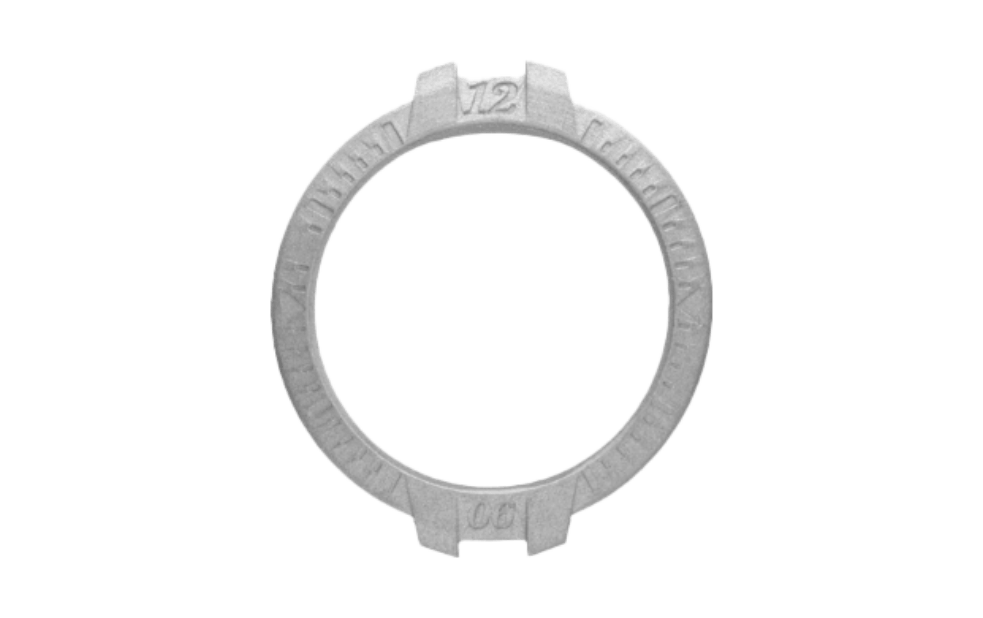

Smart watch middle frame

0.01

Time

2 hours

Layering Thickness

20-120 μm

Materials

TC4

Materials Usage

90%-95%

It shows what the metal powder materials that weused on this part by our SLM system.

Bluetooth headset mold

0.4

Time

13 hours

Layering Thickness

20-120 μm

Materials

316L

Materials Usage

90%-95%

It shows what the metal powder materials that weused on this part by our SLM system.

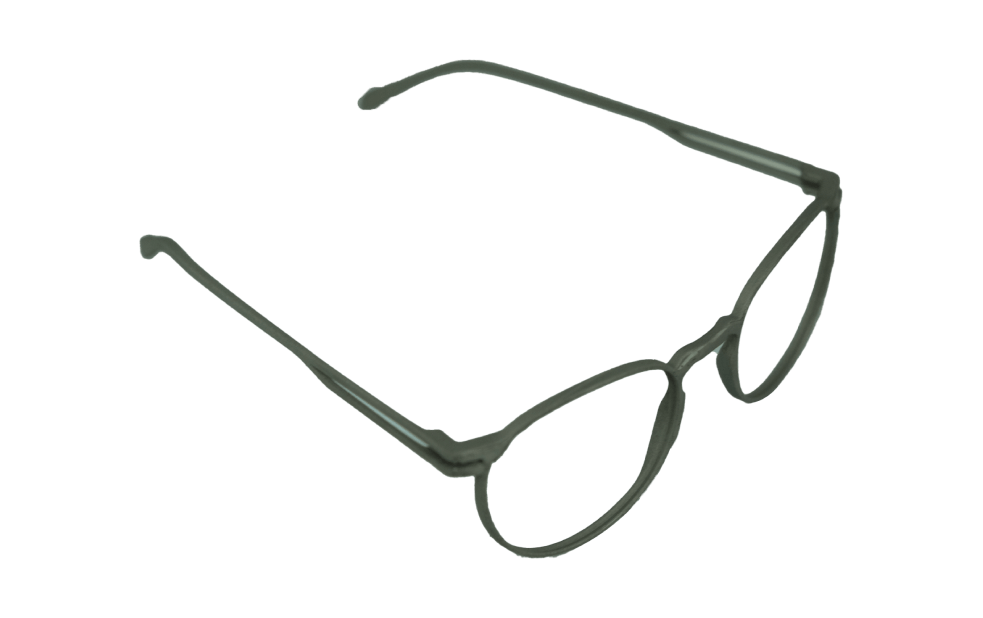

Glasses frame

0.01

Time

17 hours

Layering Thickness

20-120μm

Materials

TC4

Materials Usage

90%-95%

It shows what the metal powder materials that weused on this part by our SLM system.

Printing materials

Curious to see what the materials used in our SLM system? know more detail

about our Materials introduction for our metal 3D powder printing.

Aluminum Alloys

Stainless Steels

Titanium Alloys

Copper Alloys

Cobalt-Chromium Alloys

Precious Metals

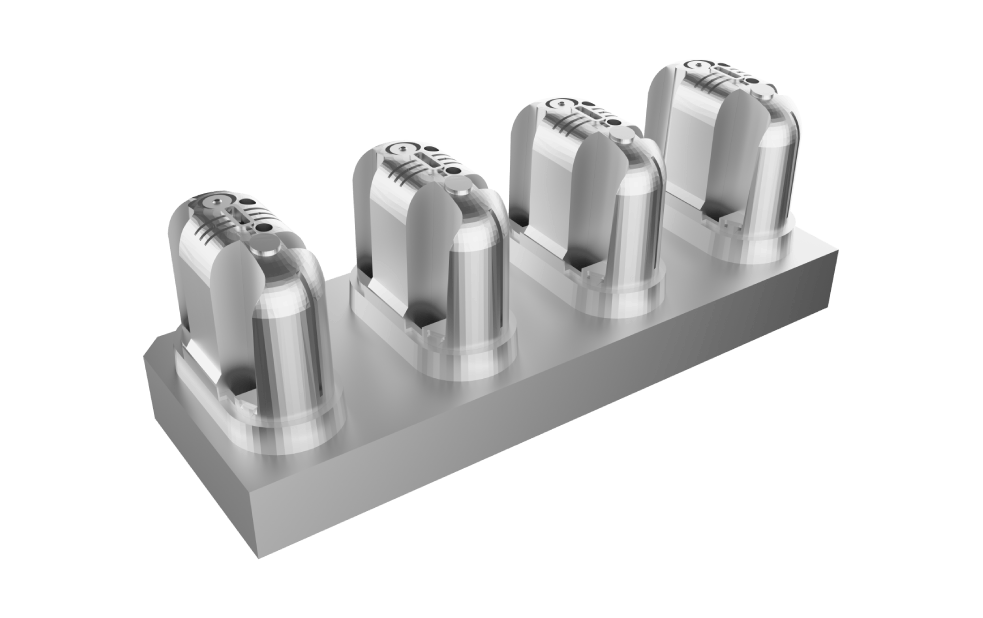

SLM system

Supports single to quad-laser configurations with adjustable formats. Designed for efficient, high-precision batch printing in mold and tooling industries.

286×286×450 mm build size with single or dual-laser options. Supports titanium, aluminum, nickel alloys, and more—perfect for aerospace and tooling applications.

Small-format design for rapid prototyping with industrial-grade metals. Supports one-button printing and remote control—ideal for research and product development.

Industry new trends

Unlocking the Future of Dental Manufacturing | Tianhong Laser to Showcase at Formnext 2025

Unique Dental Trading Corp Transforms Dental Manufacturing with LM-M100DLite Metal 3D Printer

Stahanivets CAD CAM Center Improves Dental Manufacturing with LM-M100DLite Metal 3D Printer

Find your

perfect system

Explore and compare our range of advanced systems to discover theperfect match for your additive manufacturing goals.