- HOME

- Auto Part

Auto Part

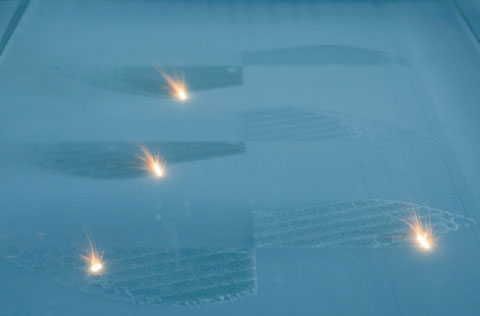

High-speed metal 3D printing for mass production

The automotive industry is rapidly evolving toward lightweight, customized, and smart manufacturing. Metal 3D printing enables greater design freedom, reduces tooling costs, and accelerates development cycles. From concept vehicles and high-performance motorsports parts to thermal management systems in EVs, metal AM is driving the next generation of automotive innovation.

What we doing

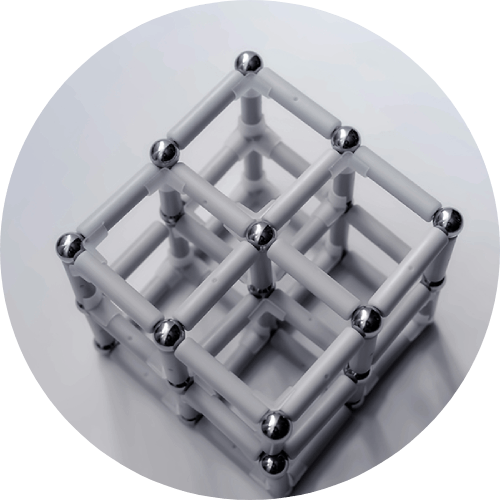

Enables Ultimate Lightweight Structures

Reduces part weight via topology optimization and hollow structures, improving fuel economy or EV range.

Supports Customization & Rapid Prototyping

Speeds up complex part prototyping and supports personalized designs, ideal for custom or racing parts.

Optimized Thermal Management Capabilities

Creates internal cooling channels and lattices for efficient thermal management.

Integrated Structures Reduce Assembly Costs

Minimizes joints and welds, reducing assembly complexity and failure risk.

customer success stories

In the metal 3D printing process, the core of process development is to optimize each step to ensure the quality and performance of the final product

这里是机器2的描述文本

这里是机器3的描述文本

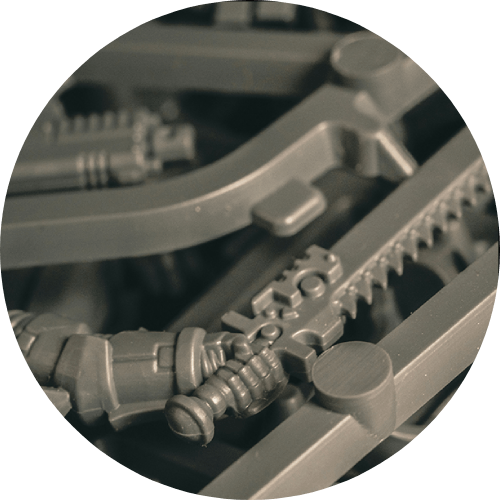

Printing Showcase

Automobile brake

3.3

Time

56 hours

Layering Thickness

20-120 μm

Materials

TC4

Materials Usage

90%-95%

It shows what the metal powder materials that weused on this part by our SLM system.

Car wheel hub

9

Time

120 hours

Layering Thickness

20-120 μm

Materials

316L

Materials Usage

90%-95%

It shows what the metal powder materials that weused on this part by our SLM system.

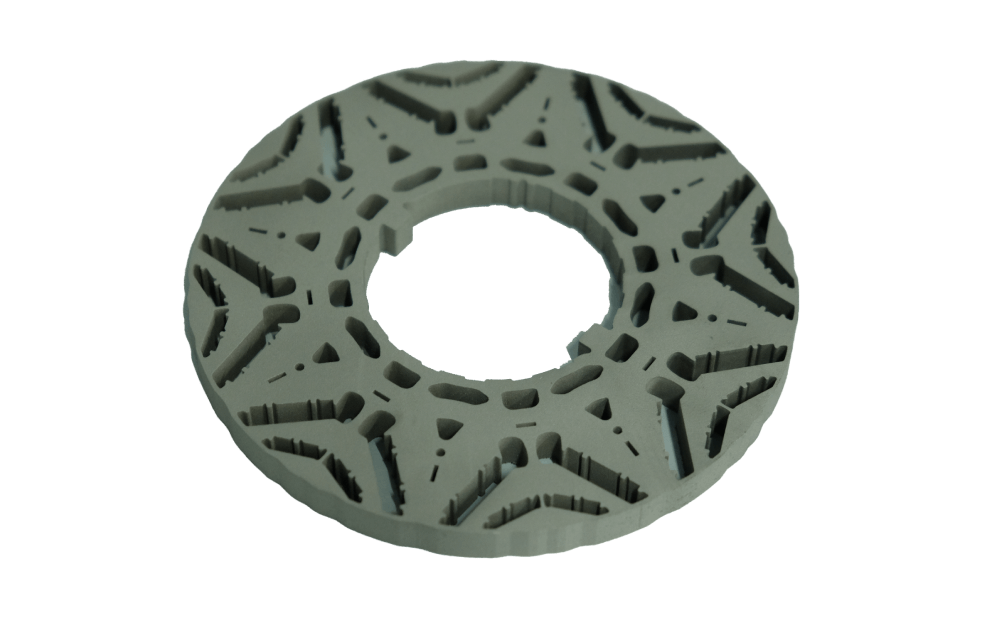

Motor rotor silicon steel sheet

0.5

Time

17 hours

Layering Thickness

20-120 μm

Materials

316L

Materials Usage

90%-95%

It shows what the metal powder materials that weused on this part by our SLM system.

Printing materials

Curious to see what the materials used in our SLM system? know more detail

about our Materials introduction for our metal 3D powder printing.

Aluminum Alloys

Titanium Alloys

Stainless Steels

Tool Steels

Copper Alloys

SLM system

807×607×900 mm build size with 4/6/8 laser options. High efficiency and precision for aerospace, molds, and automotive parts.

Supports single to quad-laser configurations with adjustable formats. Designed for efficient, high-precision batch printing in mold and tooling industries.

286×286×450 mm build size with single or dual-laser options. Supports titanium, aluminum, nickel alloys, and more—perfect for aerospace and tooling applications.

Industry new trends

Unlocking the Future of Dental Manufacturing | Tianhong Laser to Showcase at Formnext 2025

Unique Dental Trading Corp Transforms Dental Manufacturing with LM-M100DLite Metal 3D Printer

Stahanivets CAD CAM Center Improves Dental Manufacturing with LM-M100DLite Metal 3D Printer

Find your

perfect system

Explore and compare our range of advanced systems to discover theperfect match for your additive manufacturing goals.