- HOME

- FAQs

General Questions

General Questions

Categories

General Questions

What is metal 3D printing?

Metal 3D printing is an additive manufacturing process that builds parts layer by layer using fine metal powders and a high-energy source, such as a laser. It enables the production of complex, high-performance metal components directly from digital models.

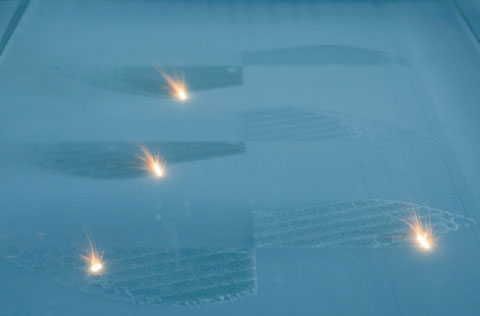

How does your SLM technology work?

Our printers use Selective Laser Melting (SLM) technology. A thin layer of metal powder is spread over the build platform, and a high-power fiber laser selectively melts the powder based on the CAD file. This process repeats layer by layer until the final 3D metal part is formed.

What are the benefits of using metal 3D printing?

Design freedom: Enables complex geometries that are difficult or impossible to machine.

Rapid prototyping: Speeds up product development with fast, direct fabrication.

Material efficiency: Minimizes waste compared to subtractive methods.

Functional integration: Allows for lightweight, multi-functional parts in a single build.

Short-run production: Ideal for customized parts and low-volume manufacturing.

Do you support custom material testing or parameter development?

Absolutely. We offer open parameter settings and technical support for R&D institutions and advanced users. You can conduct experiments with new alloys, particle sizes, and process strategies.