- HOME

- FAQs

Maintenance & Safety

Maintenance & Safety

Categories

Maintenance & Safety

What are the daily maintenance tasks?

Daily maintenance includes:

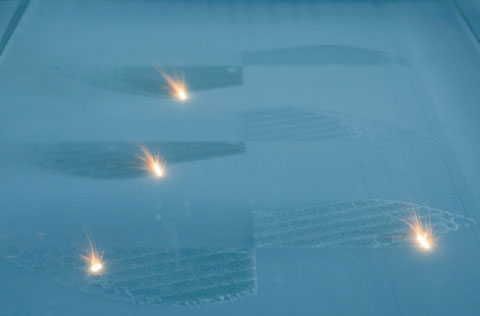

Cleaning the build chamber and recoater blade

Checking powder levels and removing unused powder

Inspecting the optical window for dust or spatter

Ensuring the gas flow system is working properly

How often should I replace the filters?

For systems with a dedicated filter unit, the filter should be replaced every 1–3 months, depending on usage. Some machines offer filter status monitoring to notify users when replacement is needed.

What safety measures should I follow during printing?

Always wear protective gloves, safety goggles, and a dust mask when handling powder

Operate in a well-ventilated area or use a fume extraction system

Store metal powders in sealed, dry containers

Avoid contact with open flames or sparks

Follow all recommended safety guidelines in the user manual

Is the machine safe for beginners to operate?

Yes. Our printers are equipped with safety interlocks, emergency stop functions, and sealed powder handling systems. With proper training, even first-time users can operate the equipment safely.

What happens in case of power failure during printing?

Our machines feature power-off recovery for specific models. If a power outage occurs, the system can resume printing from the last completed layer (if enabled), minimizing material waste and downtime.