- HOME

- Medical

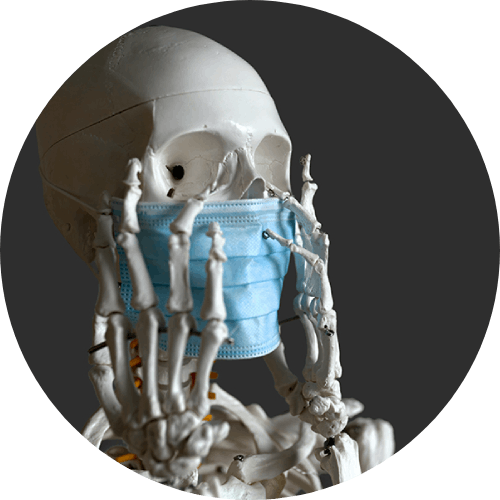

Medical Orthopedics

High-speed metal 3D printing for mass production

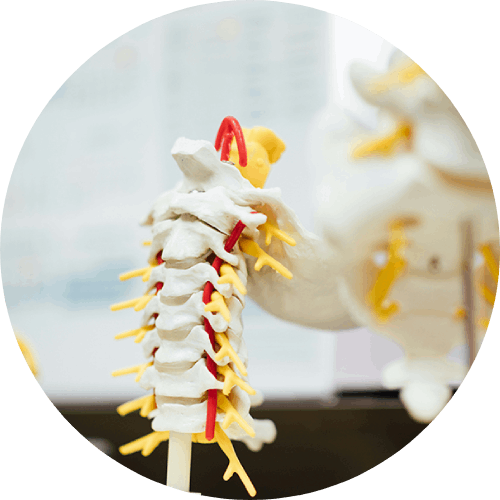

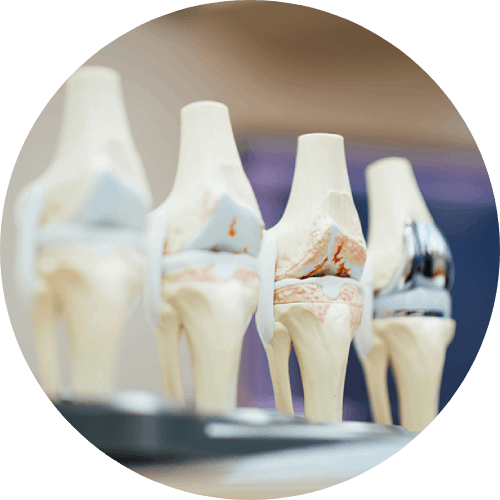

Metal 3D printing enables personalized treatment, high-fit implants, and complex reconstruction in orthopedics. It is widely used in cranio-maxillofacial reconstruction, joint replacement, and spinal correction, improving patient comfort and recovery.

What we doing

Personalized Implant Fabrication

Customize orthopedic implants based on patient CT/MRI data to achieve precise anatomical matching.

Porous Structures for Osseointegration

Porous designs mimic bone architecture, enhancing bone ingrowth and biological fixation.

One-Step Forming of Complex Geometries

Enables printing of highly complex joint or spine components with improved strength and accuracy.

Certified Biomedical Materials

Supports implant-grade titanium alloys (e.g., Ti6Al4V) with excellent biocompatibility and strength.

Rapid Prototyping & Production

Speeds up development cycles to meet fast-response medical customization needs.

customer success stories

In the metal 3D printing process, the core of process development is to optimize each step to ensure the quality and performance of the final product

这里是机器2的描述文本

这里是机器3的描述文本

Printing Showcase

Acetabular cup

0.5

Time

16 hours

Layering Thickness

20-120 μm

Materials

TC4

Materials Usage

90%-95%

It shows what the metal powder materials that weused on this part by our SLM system.

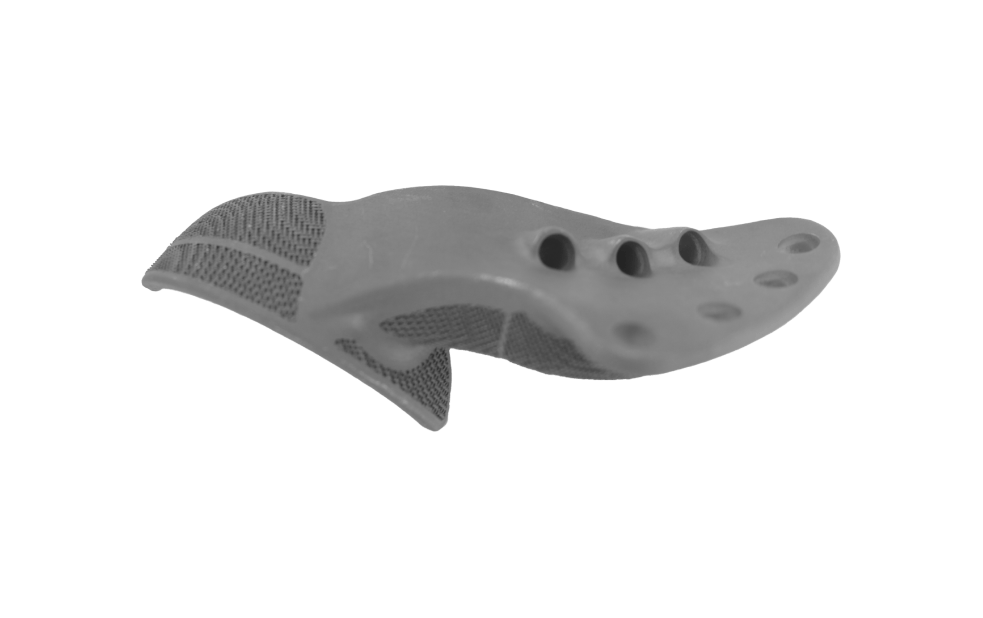

Tumor acetabular cup

0.2

Time

17 hours

Layering Thickness

10-120 μm

Materials

TC4

Materials Usage

90%-95%

It shows what the metal powder materials that weused on this part by our SLM system.

Tumor acetabular cup

0.2

Time

17 hours

Layering Thickness

10-120 μm

Materials

TC4

Materials Usage

90%-95%

It shows what the metal powder materials that weused on this part by our SLM system.

Printing materials

Curious to see what the materials used in our SLM system? know more detail

about our Materials introduction for our metal 3D powder printing.

Titanium Alloys

Stainless Steels

Cobalt-Chromium Alloys

Nickel-Titanium Alloys

Aluminum Alloys

SLM system

Supports single to quad-laser configurations with adjustable formats. Designed for efficient, high-precision batch printing in mold and tooling industries.

807×607×900 mm build size with 4/6/8 laser options. High efficiency and precision for aerospace, molds, and automotive parts.

Industry new trends

Unlocking the Future of Dental Manufacturing | Tianhong Laser to Showcase at Formnext 2025

Unique Dental Trading Corp Transforms Dental Manufacturing with LM-M100DLite Metal 3D Printer

Stahanivets CAD CAM Center Improves Dental Manufacturing with LM-M100DLite Metal 3D Printer

Find your

perfect system

Explore and compare our range of advanced systems to discover theperfect match for your additive manufacturing goals.