- HOME

- All ArticalsCompany News

All Articals, Company News

Precision Casting Metal, Shaping the Future | Linmu3D’s Successful Conclusion at TCT Asia 2025!

- 64 min read

In this article

2025 TCT Asia

From March 17th to 19th, TCT Asia 2025, the premier event for the 3D printing and additive manufacturing industry in Asia, was held at the National Exhibition and Convention Center in Shanghai. Linmu3D showcased its latest solutions with a series of metal 3D printing equipment, contributing to the high-quality development of the industry.

From March 17th to 19th, TCT Asia 2025, the premier event for the 3D printing and additive manufacturing industry in Asia, was held at the National Exhibition and Convention Center in Shanghai. Linmu3D showcased its latest solutions with a series of metal 3D printing equipment, contributing to the high-quality development of the industry.

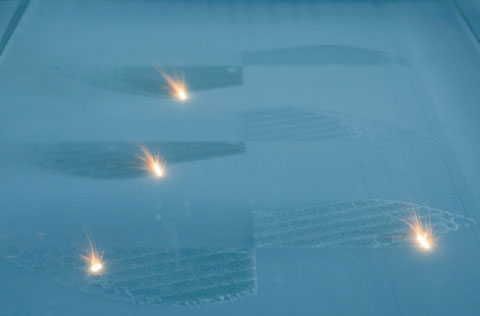

Several innovative devices were prominently featured at the exhibition.

At this exhibition, Linmu3D showcased a range of industry-leading 3D printing equipment, covering various fields such as small-scale metal printing, shoe mold manufacturing, and dental applications. This fully demonstrated Linmu3D’s technological strength and innovative capabilities in the additive manufacturing sector.

TH-M150 Metal 3D Printing Equipment

The TH-M150 is a metal 3D printing device developed by Linmu3D specifically for high-precision, small-scale metal parts. It is suitable for fields such as medical dentistry and precision molds. Its high stability and printing accuracy were highly recognized by the attendees on-site.

Another star product TH-M400 shows the deep accumulation of Linmu3D laser in the field of metal powder melting technology. The equipment has a large molding chamber of 406*406*450mm³, which can meet the needs of mass production. Its molding speed can reach up to 140 cubic centimeters per hour, providing strong technical support for the batch customization of metal materials.

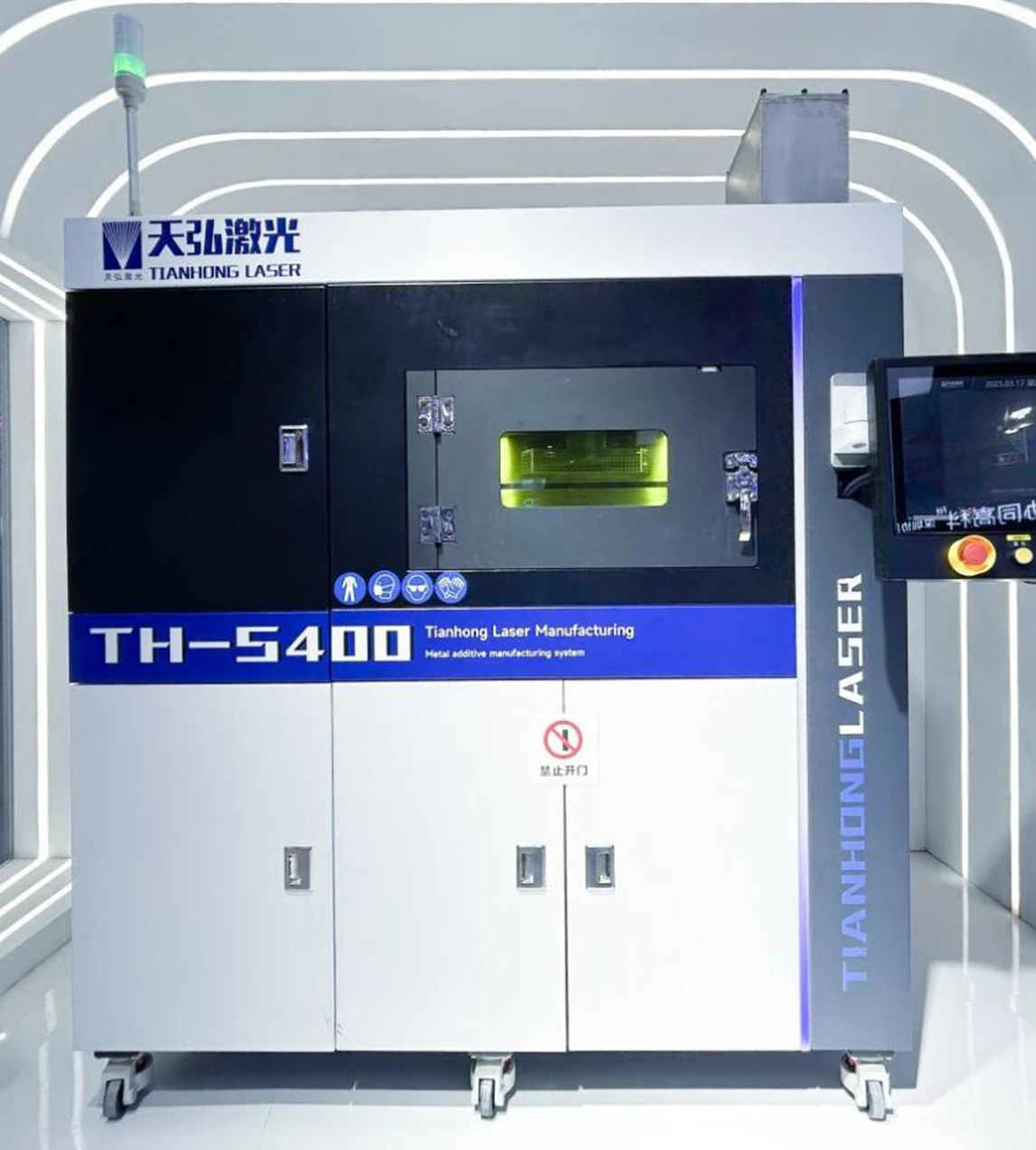

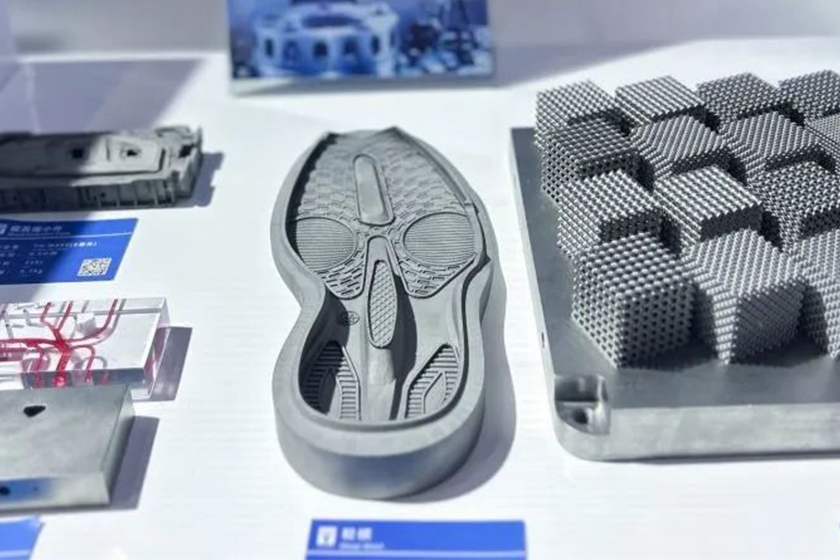

TH-S400 Shoe Mold Industry-Specific Machine

In response to the needs of the shoe mold manufacturing industry, Linmu3D introduced the TH-S400, a specialized machine for shoe molds. This device features an efficient laser system and intelligent control technology, enabling the rapid printing of complex shoe mold structures and providing an efficient solution for the footwear manufacturing industry.

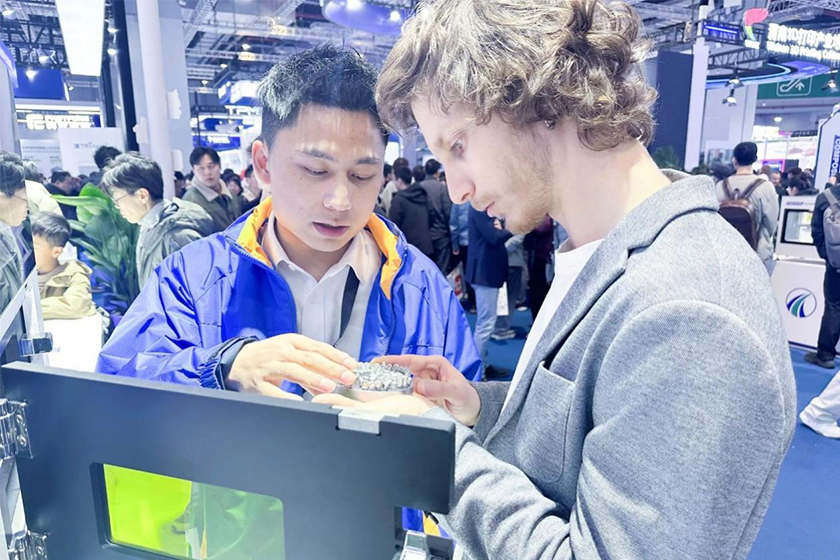

Dental-Specific Desktop Metal 3D Printer

Linmu3D’s dental-specific desktop metal 3D printer, showcased at the exhibition, has become a focal point in the medical industry due to its compact size and high-precision printing capabilities. This device can be widely used in the production of dental restorations such as crowns and bridges, providing strong technical support for personalized healthcare.

Multi-Industry Applications Showcasing Technological Strength

At the exhibition, Linmu3D displayed metal 3D printed samples from multiple industries, including aerospace, automotive manufacturing, mold industry, dental, consumer goods, crafts, and heavy industry. These samples not only highlighted Linmu3D’s deep expertise in laser process optimization but also demonstrated the company’s technological strength across various industry applications.

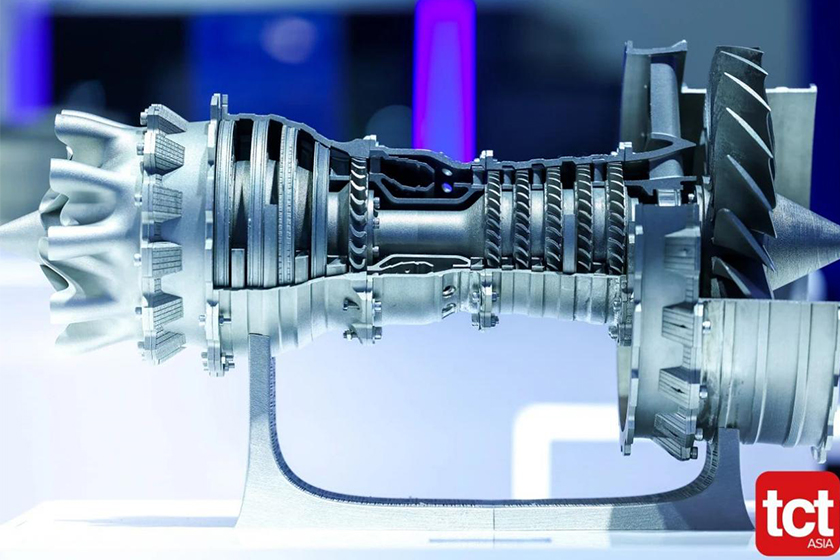

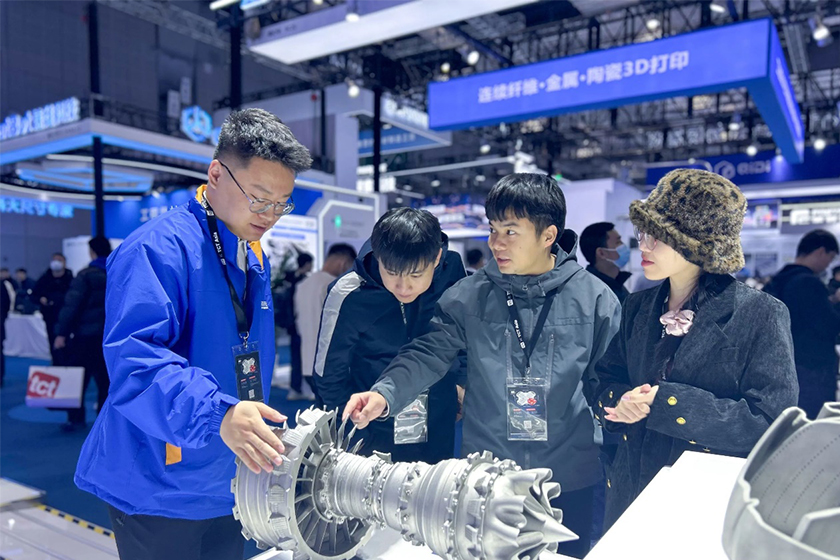

Aerospace Industry

The exhibition featured highly complex, lightweight aerospace components, demonstrating the immense potential of additive manufacturing in the aerospace sector.

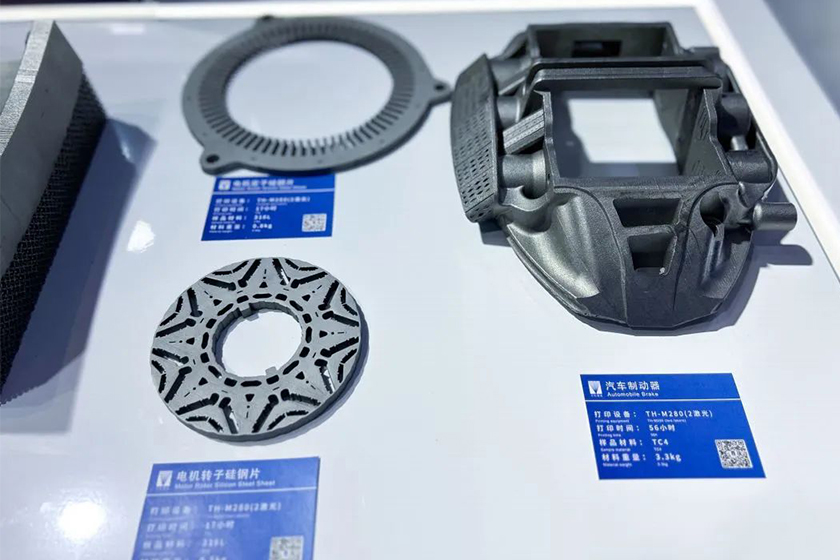

Automotive Industry

High-performance automotive components were showcased, highlighting the value of 3D printing in automotive lightweighting and customized production.

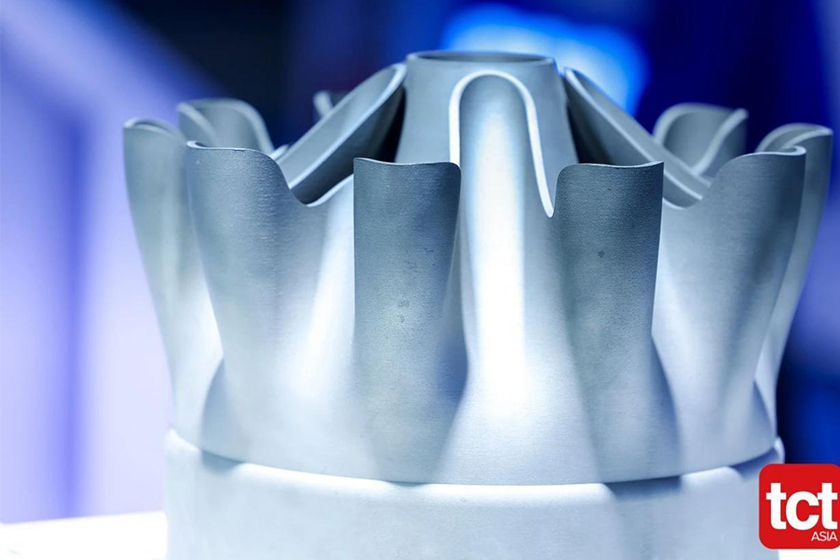

Mold Industry

High-precision mold samples were displayed, showcasing the efficiency and flexibility of 3D printing in mold manufacturing.

Medical and Dental Industry

Personalized dental restorations and high-precision orthopedic implants were showcased, attracting the attention of numerous professionals from the healthcare industry.

Consumer Goods and Crafts Industry

Exquisite metal crafts and practical consumer goods were showcased, demonstrating the vast potential of 3D printing in the consumer goods sector.

Heavy Industry Sector

Metal component samples from the heavy industry sector were showcased, highlighting Linmu3D’s technological advantages in the manufacturing of highly complex parts.

At the exhibition, Linmu3D showcased a series of equipment and industry application solutions at their booth, along with live demonstrations of typical applications and material printing. This attracted numerous customers who stopped by for discussions and exchanges.

Precision Casting Metal, Shaping the Future

TCT Asia 2025 was not only a feast of technology but also a baptism for the industry. Through this exhibition, Linmu3D not only demonstrated its technological strength and diverse application achievements but also engaged with industry peers to discuss the future development direction of additive manufacturing. Moving forward, Linmu3D will continue to deepen its expertise in laser technology and additive manufacturing, driving technological innovation and industrial applications.

TCT Asia 2025 was not only a feast of technology but also a baptism for the industry. Through this exhibition, Linmu3D not only demonstrated its technological strength and diverse application achievements but also engaged with industry peers to discuss the future development direction of additive manufacturing. Moving forward, Linmu3D will continue to deepen its expertise in laser technology and additive manufacturing, driving technological innovation and industrial applications.