| Features | |

| Dimensions: | 960x730x1788 mm3 |

| layering thickness: | 20-120 μm |

| Max Speed: | 20 cm³/h |

Filtration circulation system

Optical system

Print video available

Display interface (provide UI pictures)

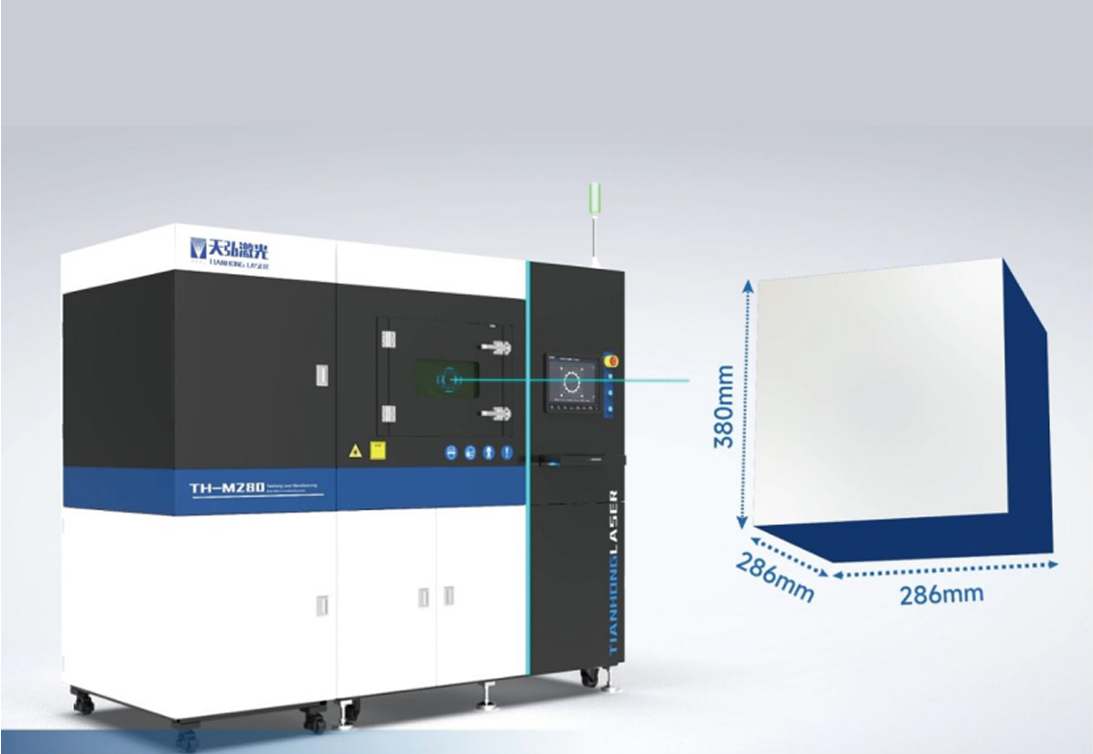

The TH-M280 gives you design freedom with its 286 x 286 x 380 mm buildvolume. The optimized optical structure enables high-quality print results even inthe corners of the substrate, without any disruptive screws on the substrate.

With full-field (2x 500 W, optionally 4x 500 W), all lasers emit beams across theentire build volume, thus shortening the production time per part - the fullyautomatic alignment of the scanning fields with each other ensures excellentprecision.

Realize real-time powder adding operation under inert gas protection, and thevolume of overflow powder cylinder and powder supply cylinder is larger. Suitablefor batch production operation.

TH3D control software can complete the entire control process from data to partprocessing and forming. Users can easily complete printing tasks by following theoperating instructions.

Lorem Ipsum Dolor Sit Amet, Consectetur Adipisicing Elit. Sed Do Eiusmod Tempor Incididunt Ut Labore Et Dolore Magna Aliqua. Ut Enim Ad Minim Veniam, Quis Nostrud Exercitation Ullamco Laboris

Explore applications for 3D printing across a range of industries

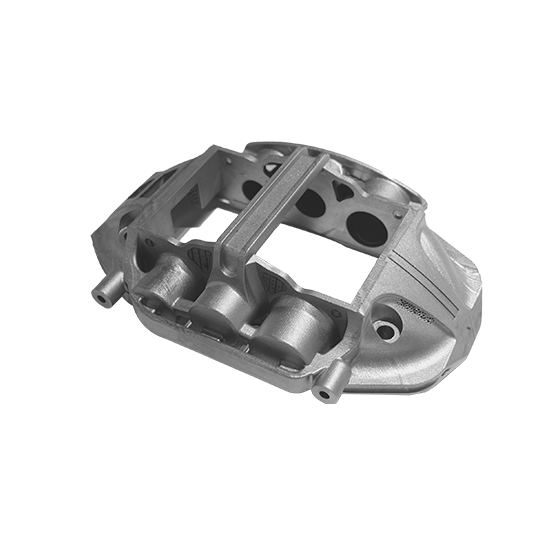

Material: AlSi10Mg

Build Time: 2lh

Application: Automotic

Material:TC4

Weight:3.3KG

Application:Automotive

Material:TC4

Weight:0.4KG

Application:Figures

Material:TC4

Weight:0.01KG

Application:3C

| Dimension | 1753x1266x2000 mm³ (Length, Width, Height) |

| Build volume | 254 x 254 x 330 mm |

| Scanning Speed | 7 m/s |

| Light Spot Diameter | 50μm-120μm |

| Light source | 500W×1/×2 |

| Powder Layering Thickness | 20μm-120μm |

| Forming Speed | Max 35cm³/h (Single laser) |

| Applicable Material | Titanium alloys, high-temperature alloys, Aluminum Alloy,stainless steel,high-strength steel,die steel,etc. |

| Chamber Oxygen Level | ≤100ppm |

| Electrical Consumption | 380V, 34 KW |

| Protective Gas | Nitrogen/Argon |

| Data Format | STL or other Convertible File |

| Complementary software | TH-3Dprint |

| Electrical consumption | 380V, 12.5KW |

| Weight | 1.5T |

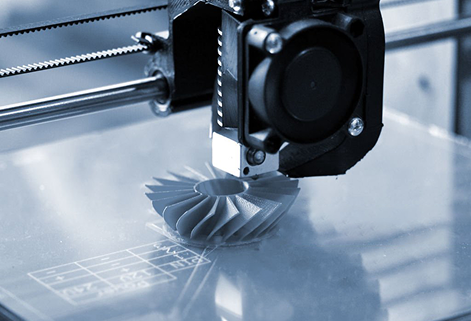

Metal 3D Printing is a cutting-edge additive manufacturing technology that builds fully dense metal parts directly from digital designs. Using high-precision lasers to selectively melt fine metal powders layer by layer, it enables unparalleled design freedom, exceptional detail, and performance-grade strength.

Our R&D team is dedicated to improving printing accuracy and production efficiency through precise laser parameter control,

temperature management, and material parameter adjustments

Our engineers will help select the best-fit solution based on your part complexity, material, and production needs.

807×607×900 mm build size with 4/6/8 laser options. High efficiency and precision for aerospace, molds, and automotive parts.

286×286×450 mm build size with single or dual-laser options. Supports titanium, aluminum, nickel alloys, and more—perfect for aerospace and tooling applications.

Small-format design for rapid prototyping with industrial-grade metals. Supports one-button printing and remote control—ideal for research and product development.

406×206×230 mm build area with 20 μm resolution. Captures fine sole textures and logos. Optimized powder system for stable shoe mold production.

Linmu3D Limited 2025