| Features | |

| Dimensions: | 2960x12706x2500 mm3 |

| layering thickness: | 20-120 μm |

| Max Speed: | 140 cm³/h (four lasers) |

Observation window

Electrical control cabinet

Material receiving area

Forming area (Print video provided)

The XY axis forming size is the highest among similar products, and it is equippedwith 4*500W lasers as standard, with a maximum forming efficiency of 140cm3/hand high printing efficiency, Advanced multi-laser scanning strategy and calibra-tion algorithm ensure high printing efficiency and controllable quality.

Quad-laser configuration, each laser achieves full coverage of the build areausing a sophisticated scanning strategy to achieve uniform energy control withinthe build area.

Short sieving times for large powder volumes and a closed powder circulationoop provide high production efficiency and operational safety. The entire processchain can also be operated in a protective gas atmosphere: sieving, printing,cooling, de-powdering.

The software, algorithm and control system are independently developed by Linmu3Dto ensure information security and technical controllability. The process parametersare open source and personalized customization can meet diverse production needs.

Lorem Ipsum Dolor Sit Amet, Consectetur Adipisicing Elit. Sed Do Eiusmod Tempor Incididunt Ut Labore Et Dolore Magna Aliqua. Ut Enim Ad Minim Veniam, Quis Nostrud Exercitation Ullamco Laboris

Explore applications for 3D printing across a range of industries

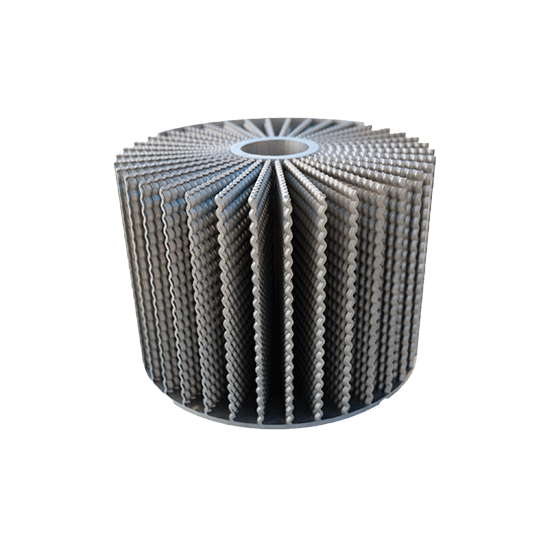

Material:316L

Weight:15KG

Application:Energy

Material:316L

Weight:9KG

Application:Automotive

Material:316L

Weight:1.2KG

Application:Mold

| Dimension | 2960x1270x2500 mm³ (Length, Width, Height) |

| Forming Cylinder Size | 406 x 406 x450 mm |

| Scanning Speed | 4×7 m/s |

| Light Spot Diameter | 70μm-120μm |

| Light source | 4x500W |

| Powder Layering Thickness | 20μm-120μm |

| Forming Speed | Max 140 cm3/h (four lasers) |

| Applicable Material | Titanium alloys, high-temperature alloys, stainless steel, high-strength steel, die steel, etc |

| Chamber Oxygen Level | ≤100ppm |

| Electrical Consumption | 380V, 34 KW |

| Weight | 4.2T |

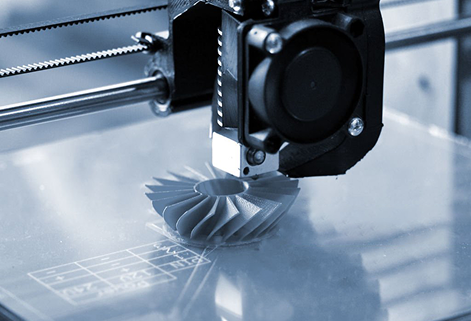

Metal 3D Printing is a cutting-edge additive manufacturing technology that builds fully dense metal parts directly from digital designs. Using high-precision lasers to selectively melt fine metal powders layer by layer, it enables unparalleled design freedom, exceptional detail, and performance-grade strength.

Our R&D team is dedicated to improving printing accuracy and production efficiency through precise laser parameter control,

temperature management, and material parameter adjustments

Our engineers will help select the best-fit solution based on your part complexity, material, and production needs.

807×607×900 mm build size with 4/6/8 laser options. High efficiency and precision for aerospace, molds, and automotive parts.

286×286×450 mm build size with single or dual-laser options. Supports titanium, aluminum, nickel alloys, and more—perfect for aerospace and tooling applications.

Small-format design for rapid prototyping with industrial-grade metals. Supports one-button printing and remote control—ideal for research and product development.

406×206×230 mm build area with 20 μm resolution. Captures fine sole textures and logos. Optimized powder system for stable shoe mold production.

Linmu3D Limited 2025