- HOME

- Shoes Mold

Shoes Mold

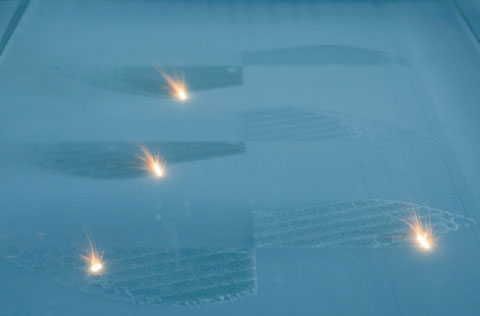

High-speed metal 3D printing for mass production

Metal 3D printing revolutionizes shoe mold manufacturing by enabling complex textures, integrated structures, and fast delivery. It empowers the footwear industry to achieve flexible and efficient production from design to mold.

What we doing

High-Precision Printing of Complex Textures

Directly prints intricate patterns, textures, and brand logos in one step, eliminating the need for engraving.

Modular & Integrated Structural Design

Supports both modular and integrated structures, enhancing durability and reducing assembly.

Rapid Prototyping & Delivery

Greatly reduces lead times from design to finished molds, ideal for fast fashion and custom shoes.

Lightweight & Wear-Resistant Materials

Utilizes CoCr alloys and similar materials with excellent wear resistance and strength for longer mold life

Eco-Friendly Manufacturing with Less Waste

On-demand shaping with high material utilization reduces waste from traditional CNC milling.

customer success stories

In the metal 3D printing process, the core of process development is to optimize each step to ensure the quality and performance of the final product

这里是机器2的描述文本

这里是机器3的描述文本

Printing Showcase

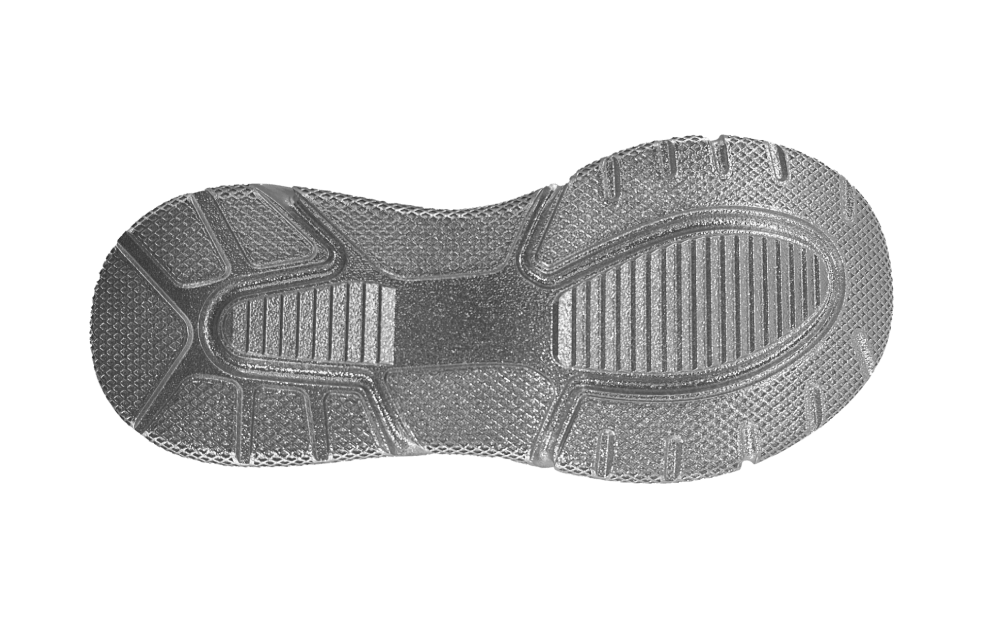

Shoe Model

28.5*13.85*6

Time

21 hours

Layering Thickness

20-120 μm

Materials

316L

Materials Usage

90%-95%

It shows what the metal powder materials that weused on this part by our SLM system.

Shoe Model

20.5*7.9*6.5

Time

21 hours

Layering Thickness

20-120μm

Materials

316L

Materials Usage

90%-95%

It shows what the metal powder materials that weused on this part by our SLM system.

Shoe Model

30.8*18.5*7.7

Time

38 hours

Layering Thickness

20-120μm

Materials

316L

Materials Usage

90%-95%

It shows what the metal powder materials that weused on this part by our SLM system.

Shoe Model

20.6*8.5*4.9

Time

17 hours

Layering Thickness

20-120μm

Materials

316L

Materials Usage

90%-95%

It shows what the metal powder materials that weused on this part by our SLM system.

Printing materials

Curious to see what the materials used in our SLM system? know more detail

about our Materials introduction for our metal 3D powder printing.

Tool Steels

Stainless Steels

Aluminum Alloys

Copper Alloys

SLM system

406×206×230 mm build area with 20 μm resolution. Captures fine sole textures and logos. Optimized powder system for stable shoe mold production.

286×286×450 mm build size with single or dual-laser options. Supports titanium, aluminum, nickel alloys, and more—perfect for aerospace and tooling applications.

Small-format design for rapid prototyping with industrial-grade metals. Supports one-button printing and remote control—ideal for research and product development.

Industry new trends

Unlocking the Future of Dental Manufacturing | Tianhong Laser to Showcase at Formnext 2025

Unique Dental Trading Corp Transforms Dental Manufacturing with LM-M100DLite Metal 3D Printer

Stahanivets CAD CAM Center Improves Dental Manufacturing with LM-M100DLite Metal 3D Printer

Find your

perfect system

Explore and compare our range of advanced systems to discover theperfect match for your additive manufacturing goals.