- HOME

- Uncategorized

RGK + Z&A Group Advances Dental Manufacturing with TH-M150 Metal 3D Printer

Project:

Printing Service

Technology:

Metal 3D powder printing

Complated:

Summer 2019

Advanced Innovation Through Additive Manufacturing

Customer Profile

RGK + Z&A Group, based in Myanmar, operates across healthcare and industrial sectors. Their dental division focuses on producing high-precision metal components such as removable partial denture (RPD) frameworks, custom abutments, and crowns for local dental clinics and laboratories.

Before: Limitations of Traditional Dental Manufacturing

Traditionally, the team relied on manual casting and CNC machining to produce dental metal parts. This process presented several challenges:

Labor-intensive wax modeling and casting steps

High rejection rates due to human error and material inconsistencies

Long lead times (up to 7–10 days per batch)

Difficulty in producing complex and lightweight structures like mesh or hollow frameworks.

Our Solution: TH-M150 for Digital Dental Production

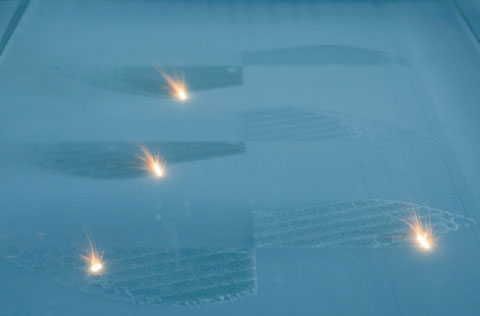

RGK + Z&A Group adopted the TH-M150 metal 3D printer from Suzhou Linmu3D to digitalize their dental production. With its 153×153×120 mm build area and 20–60 μm layer thickness, the TH-M150 is ideal for printing small, detailed dental parts in CoCr and Ti6Al4V.

Results

Lead time reduced to 2–3 days per case

Achieved precision tolerances within ±0.05 mm for dental frameworks

Enabled batch production: over 40 frameworks printed per build

Improved patient fit and reduced clinic remakes

Digital workflow allows fast customization and reprint from stored STL files

“The TH-M150 transformed our dental workflow—from slow, manual casting to digital, repeatable, and highly accurate production. Now we can deliver more cases faster and with better consistency.”

— Dental Production Manager, RGK + Z&A Group

Tumor-acetabular-cup

Acetabular-cup