30%-50% Energy Saving

Fully Electric Blow Molding Machine

LINMU Metal AM Sloutions

Dimensions

2536x1270x2230 mm

layering Thickness

20-120 μm

Consumption

380 V, 14 KW

Dimensions

3440x1270x2500 mm

layering Thickness

20-120 μm

Consumption

380 V, 34 KW

Dimensions

6584x3780x4200 mm

layering Thickness

20-120 μm

Consumption

380 V, 36 KW

Dimensions

700x700x1300 mm

layering Thickness

20-50 μm

Laser Power

380 V

Dimensions

550x550x800 mm

layering Thickness

20-60 μm

Consumption

220 V

Dimensions

960x760x1788 mm

layering Thickness

20-120 μm

Consumption

380 V, 4.1 KW

Dimensions

1770x1260x1900 mm

layering Thickness

50-100 μm

Consumption

380 V, 19 KW

Dimensions

2536x1270x2230 mm

layering Thickness

20-120 μm

Consumption

380 V, 14 KW

Build Volume

406x406x450 mm³

layering Thickness

20-120 μm

Consumption

380 V, 34 KW

Build Volume

807x607x900 mm³

layering Thickness

20-120 μm

Consumption

380 V, 36 KW

Build Volume

960x730x1788 mm³

layering Thickness

20-120 μm

Consumption

380 V, 4.1 KW

Build Volume

406x206x230 mm³

layering Thickness

50-100 μm

Consumption

380 V, 19 KW

Dimensions

960x760x1788 mm

layering Thickness

20-120 μm

Consumption

380 V, 4.1 KW

Build Volume

Ф120x100/Ф100x80 mm

layering Thickness

20-50 μm

Laser Power

300 W

Build Volume

Ф100*50mm

layering Thickness

20-60 μm

Consumption

200 V

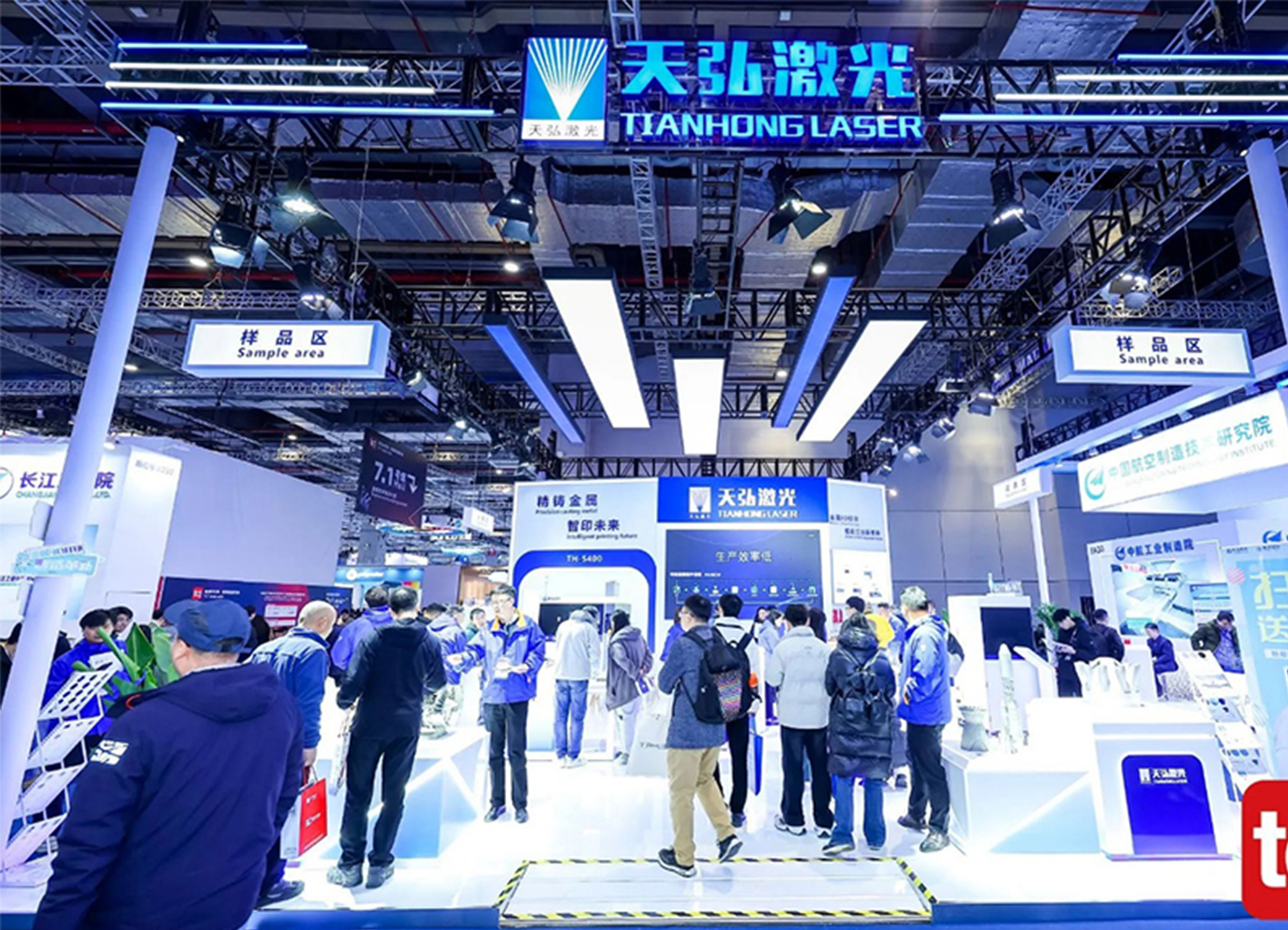

Innovation in Metal AM

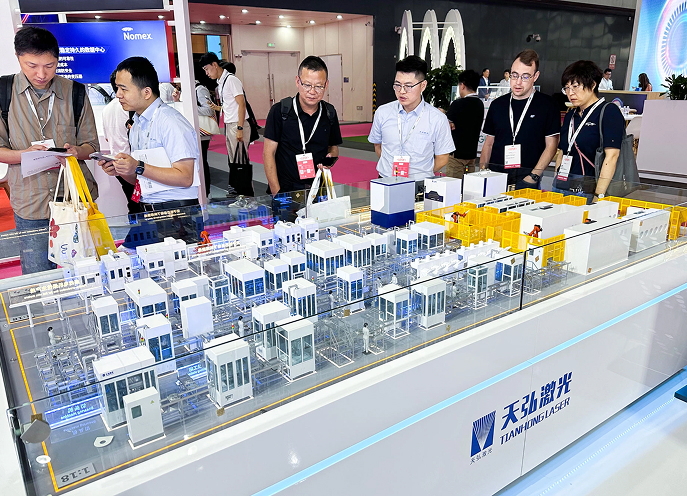

Complete 3D Printing Solutions

Smart & Efficient Manufacturing

Technology Innovation Leading Additive Manufacturing

End-to-End Solutions

Smart Manufacturing, Value Upgrading

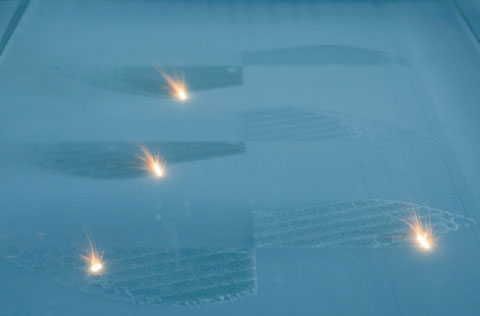

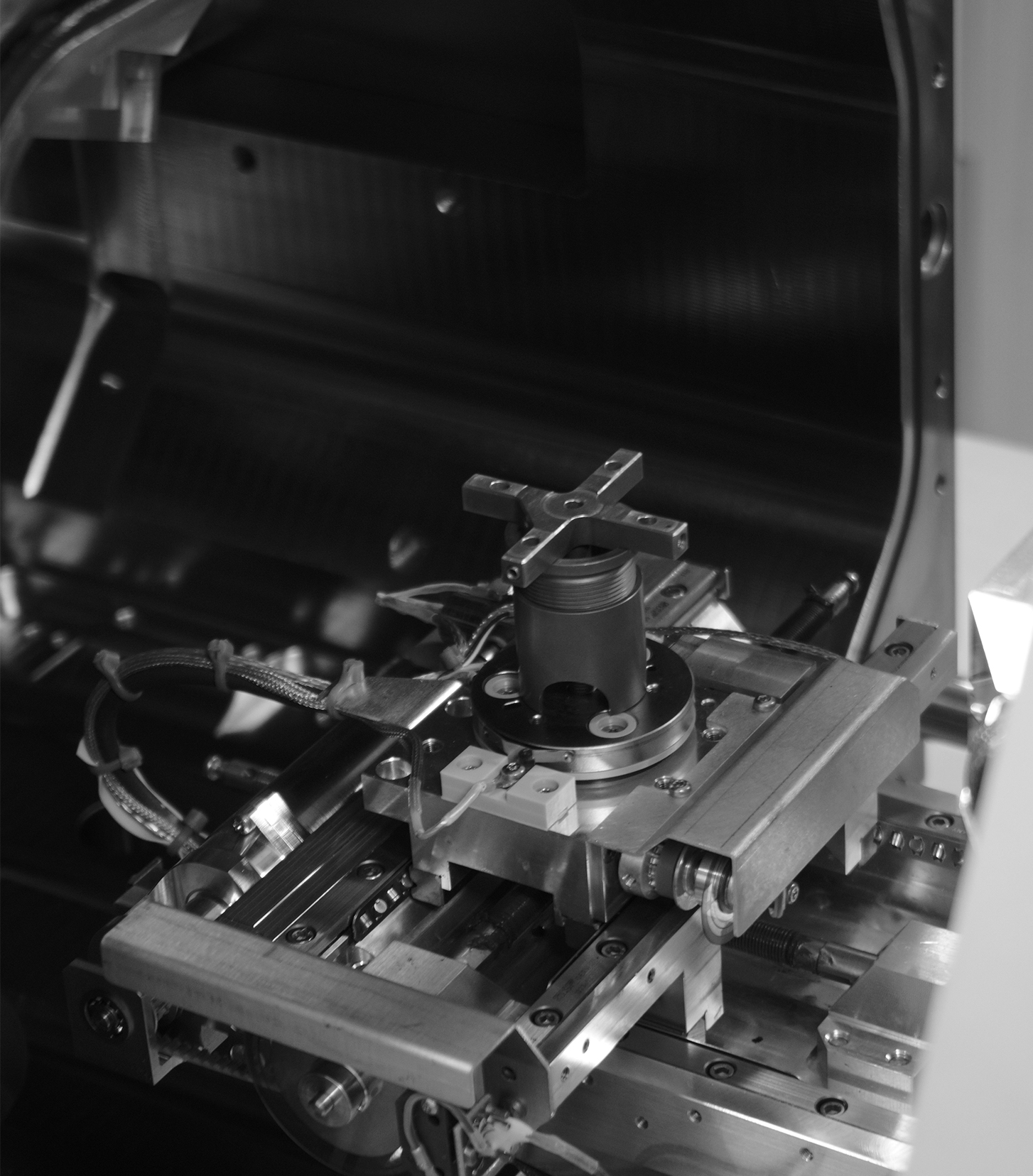

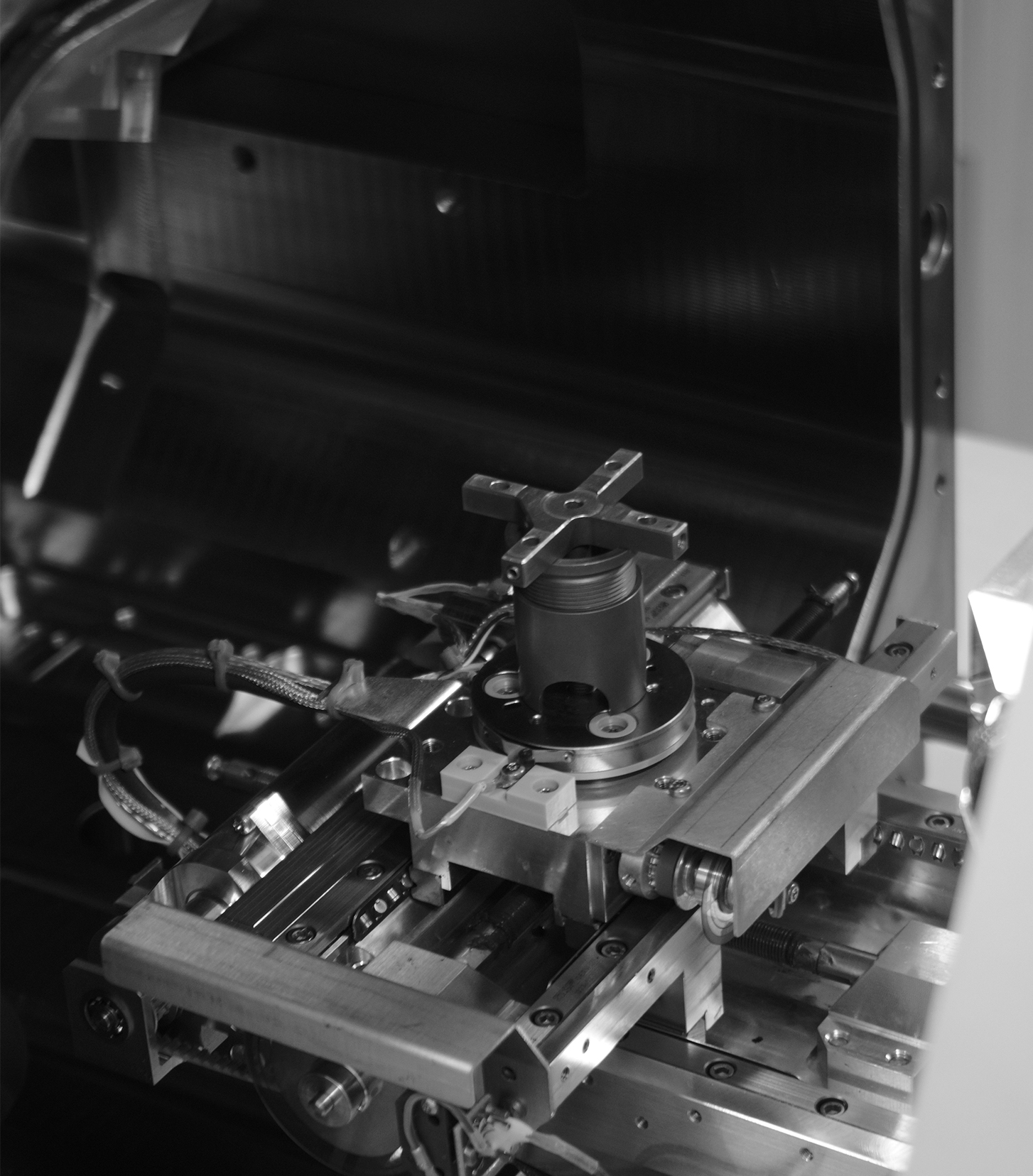

SLM Solutions

Transforming Industries with Metal 3D Printing

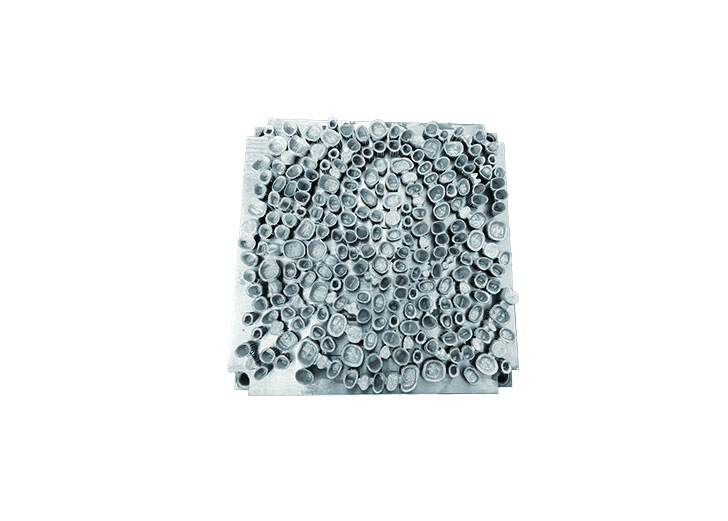

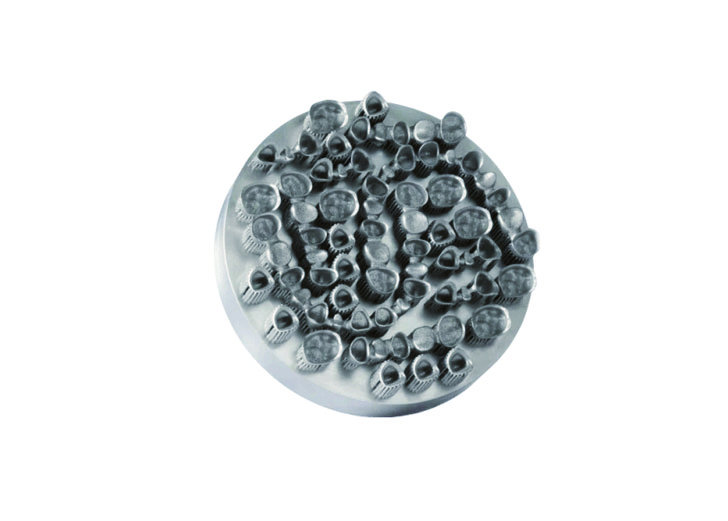

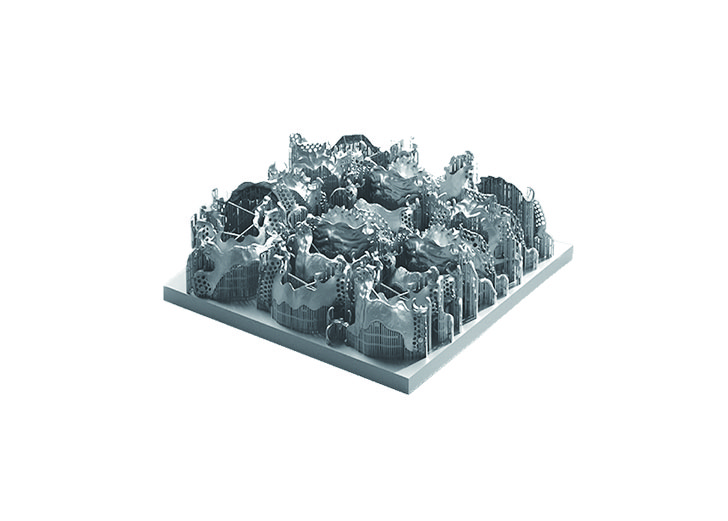

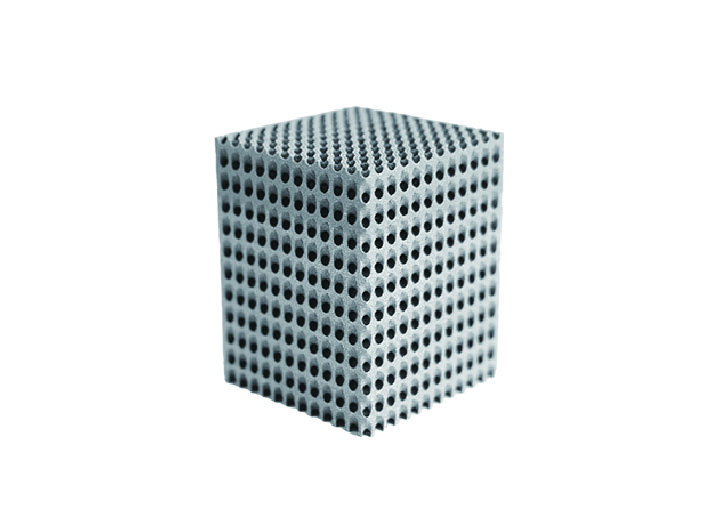

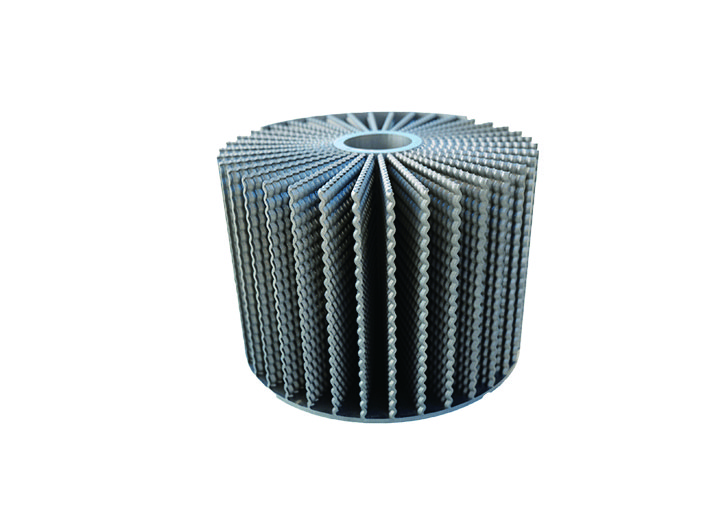

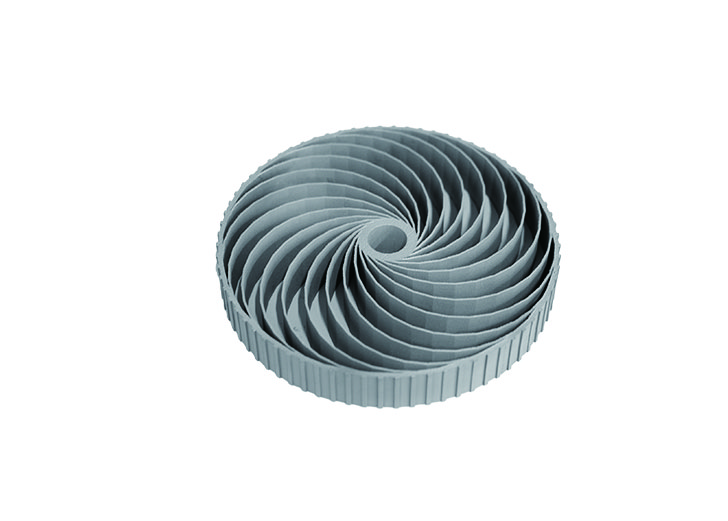

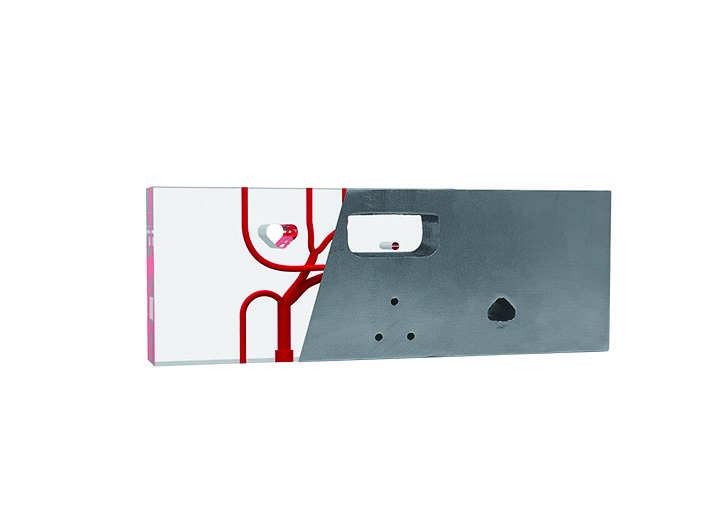

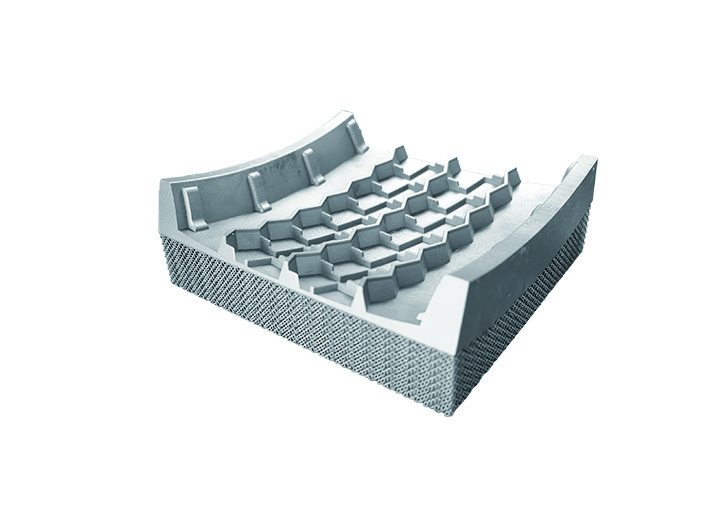

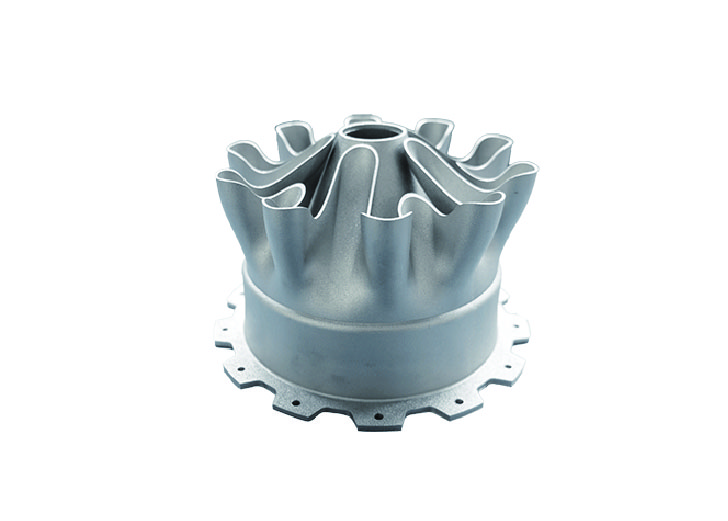

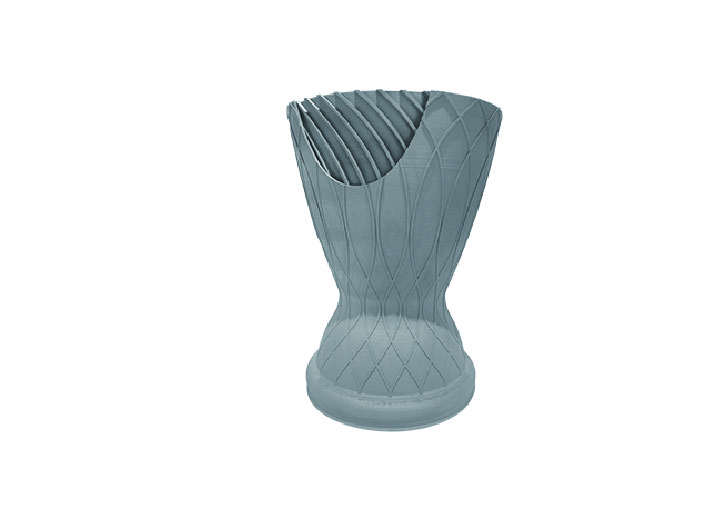

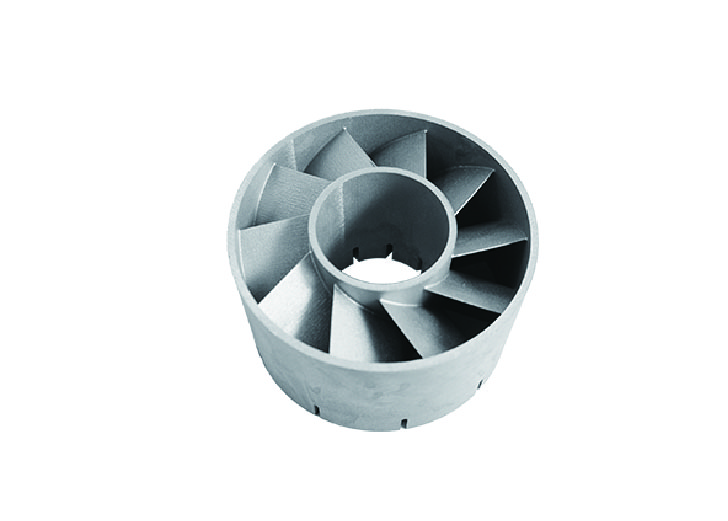

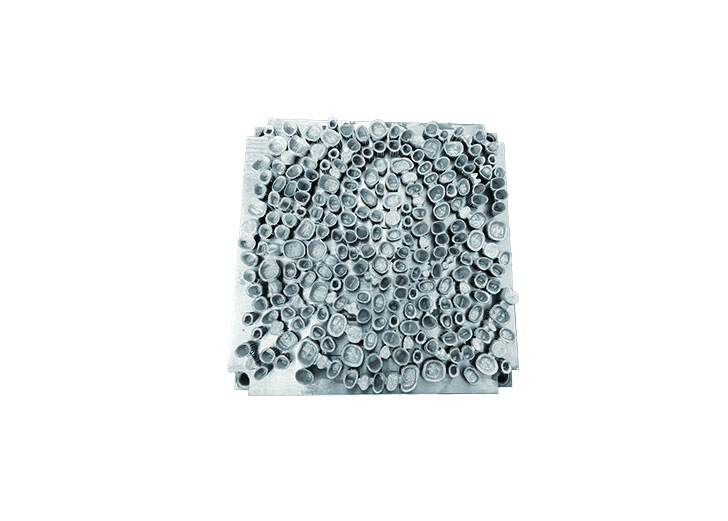

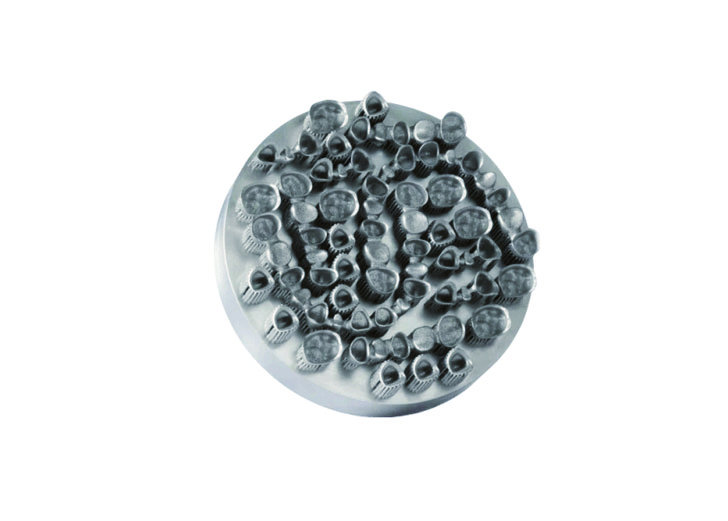

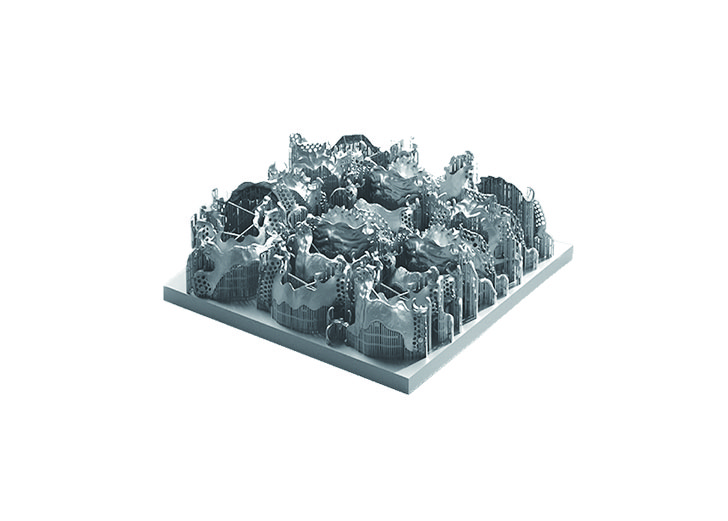

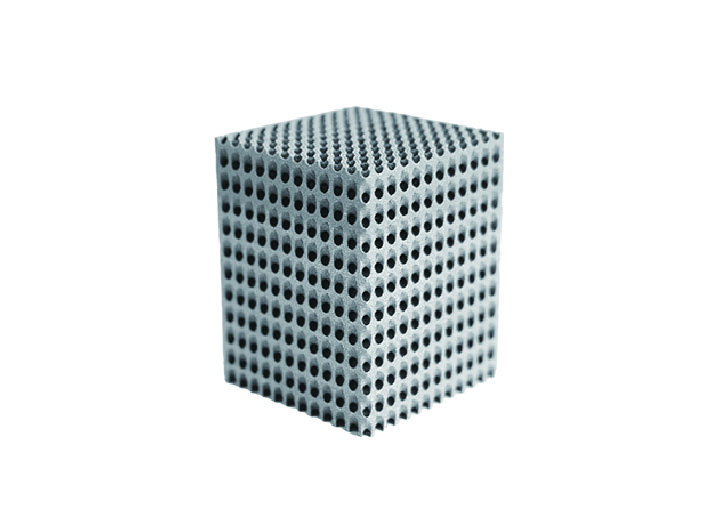

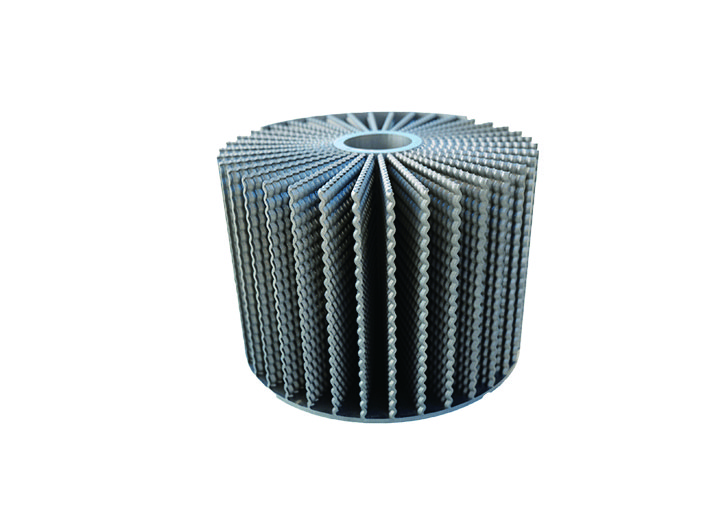

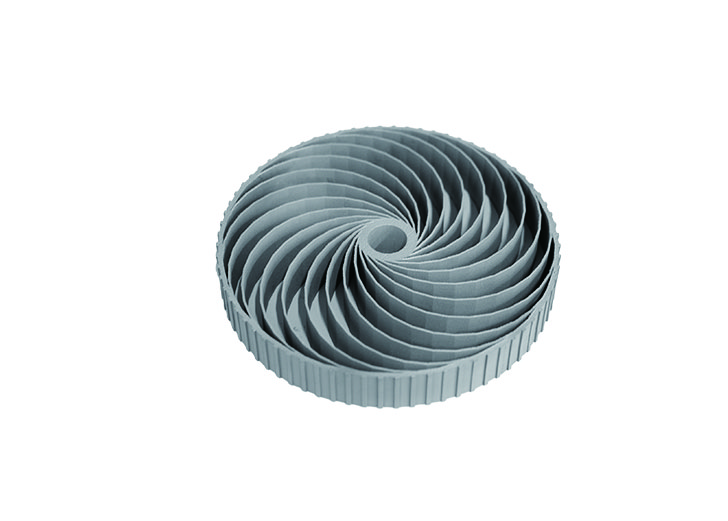

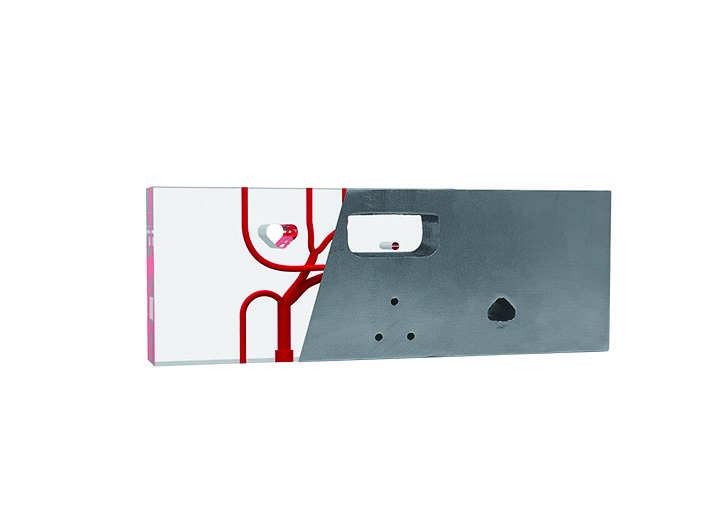

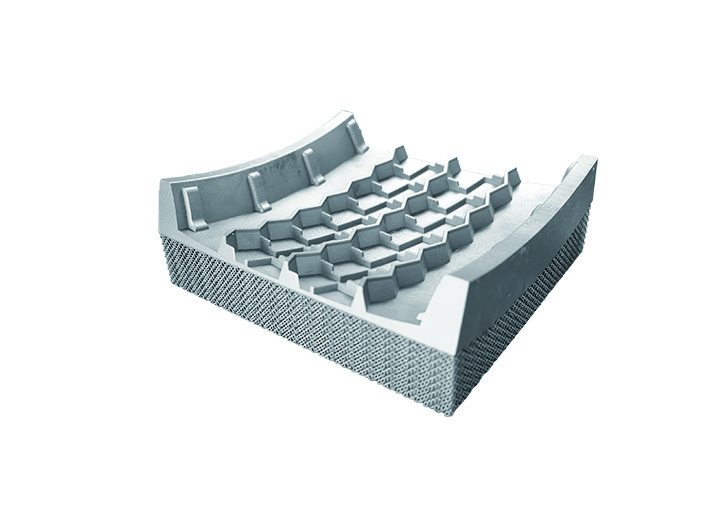

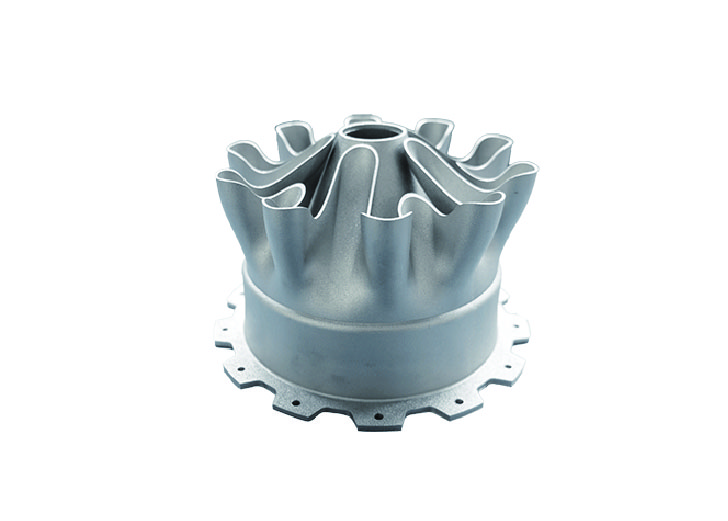

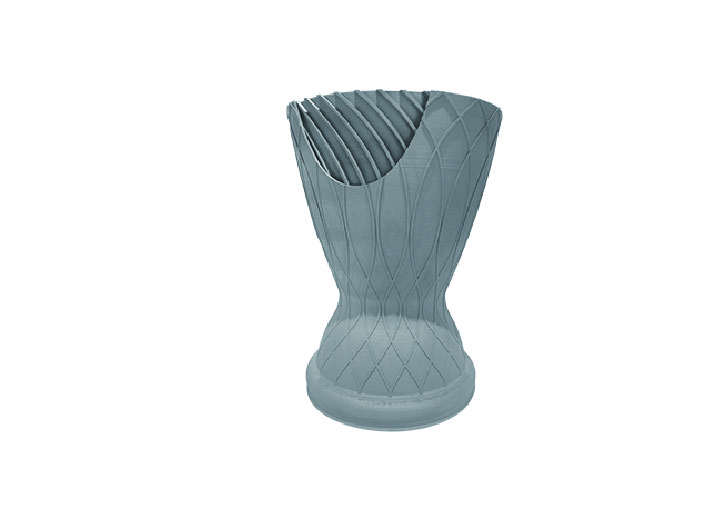

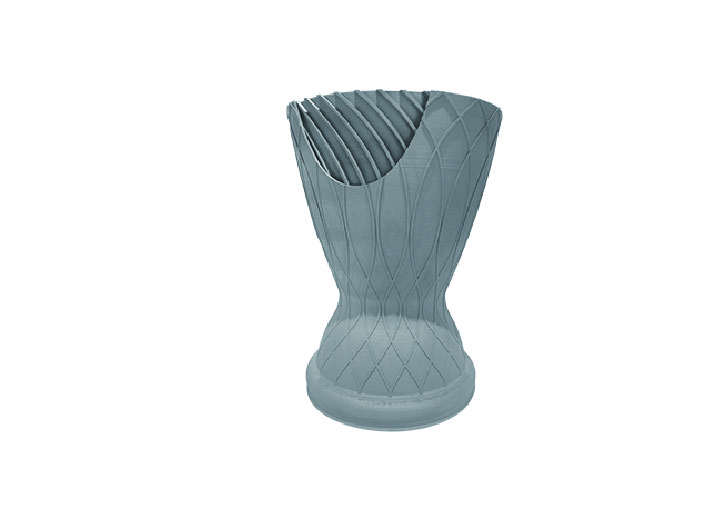

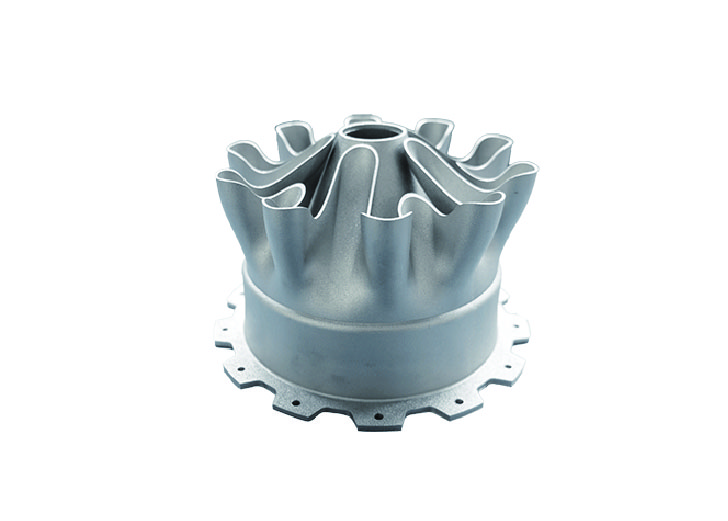

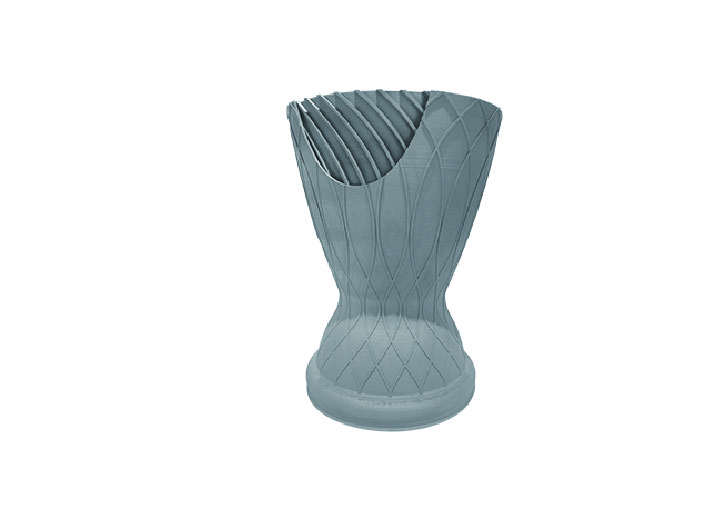

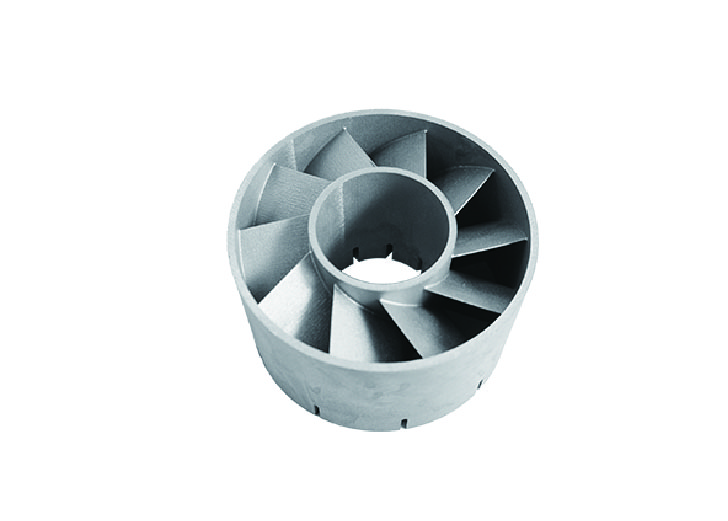

GLANCE OF SAMPLES

Acetabular cups

Denture

Denture

Oral stents

Tumor acetabular cup

Cooling lattice

Heat sink

Impeller

Accompanying waterways

Automobile door frame mold

Tire mold

Bluetooth headset mold

Glasses frames

Watch middle frame

Aero engine tail skirt

Aerospace bearings

Aviation imitation parts

Heavy-duty nozzle bureau parts

Automobile brakes

Car wheels

Electronic rotor silicon steel sheet

Shoe mold 1

Shoe mold 2

Shoe molds 3

Monkey king

Nezha

calabash

Dental

Metal 3D printing technology enables efficient production of complex structures like crowns, bridges, and partial dentures. Using high-performance cobalt-chrome alloys, we ensure excellent strength and biocompatibility for safe, stable clinical use. Exceptional accuracy and fit make our solution ideal for the digital transformation of dental manufacturing.

Energy

Metal 3D printing is widely used in the energy sector for producing critical components like heat exchangers and gas turbine parts. By optimizing designs, reducing material waste, and enhancing high-temperature and corrosion resistance, we provide more efficient and reliable solutions for energy equipment.

Mold Manufacturing

Metal 3D printing breaks the limitations of traditional mold manufacturing by rapidly producing complex cooling channels and structural components. It significantly shortens production cycles and improves mold lifespan and performance. Whether for injection molds or casting molds, we offer customized solutions with exceptional precision and strength.

Consumer Electronics

Metal 3D printing drives rapid prototyping and customized production in the consumer electronics industry. From enclosures and brackets to heat dissipation components, 3D printing offers greater design freedom, optimizing both performance and cost to meet the fast-evolving market demands.

Aerospace

Metal 3D printing enables the integration of complex geometries with reduced weight and enhanced mechanical and thermal performance. Ideal for engine components, brackets, and cooling structures, our solutions accelerate innovation and boost aerospace reliability.

Automotive

Metal 3D printing is widely used in the automotive industry for manufacturing engine components, drivetrains, radiators, and custom parts. By optimizing designs and reducing part count, we enhance component strength, durability, and lightweight characteristics, driving vehicle performance improvements and fuel efficiency optimization.

Shoes Mold

Metal 3D printing offers unparalleled design flexibility and accuracy in shoe mold manufacturing. By rapidly producing complex mold structures and optimizing cooling channels and strength distribution, we shorten production cycles and enhance mold lifespan, driving efficient production and customized design.

Education & Scientific Research

Metal 3D printing empowers research institutions and educational fields by enabling the rapid production of complex models and prototypes. Whether for experimental research, educational demonstrations, or design validation, 3D printing offers unmatched precision and flexibility, driving academic research and technological advancement.

Manufacturing relationships. Distributing quality

Wide Involved

“We chose Linmu3D’s metal 3D printer for its aerospace-grade precision and reliability. The ability to print complex parts in a single build has enhanced our design capabilities and significantly reduced development time.”

“By using metal 3D printing for engine and custom components, we’ve achieved lightweight designs and improved overall performance. Linmu3D’s equipment is reliable and has become a key tool in our manufacturing innovation.”

“In fast-paced product development, Linmu3D’s metal 3D printers provide an ideal solution for rapid prototyping. With high precision and quick turnaround, we’ve significantly shortened our design-to-validation cycle.”

“Components operating under extreme conditions demand top-tier materials and precision manufacturing. Linmu3D’s metal 3D printing solutions have enabled rapid design validation and the production of high-strength, corrosion-resistant parts.”

“We have successfully developed multiple personalized implant prototypes using this metal 3D printing device. The printing accuracy is high and the structural complexity fully meets clinical requirements, which greatly accelerates our product development cycle.”

“Traditional mold-making is time-consuming and rigid. Linmu3D’s metal 3D printing technology allows us to rapidly produce complex structures with optimized cooling designs, significantly improving mold lifespan.”

“Shoe mold designs change rapidly and demand both speed and structural complexity. Linmu3D’s metal 3D printing solution enables us to respond quickly with high-precision, fully integrated mold production.”

Events calendar

- 25th - 27th Jun, 2025 09:30 aM - 5:00 PM

- Shanghai World Expo Exhibition & Convention Center, shanghai, china