- HOME

- CaseMedical Orthopedics

Unique Dental Trading Corp Transforms Dental Manufacturing with LM-M100DLite Metal 3D Printer

Project:

Printing Service

Technology:

Metal 3D powder printing

Complated:

Summer 2019

Advanced Innovation Through Additive Manufacturing

Customer Profile

Unique Dental Trading Corp is a leading dental equipment supplier in Lahore, Pakistan, offering high-quality dental materials and equipment. The company provides innovative solutions to dental laboratories, clinics, and educational institutions across the region.

“Integrating the LM-M100DLite into our workflow has completely transformed the way we produce dental parts. We’ve cut production times, saved costs, and can now offer even more precise, customized solutions for our clients.”

— Technical Director, Unique Dental Trading Corp

Limited Design Flexibility: Traditional methods restricted the ability to produce intricate, customized designs, often requiring expensive molds or fixtures for unique dental restorations.

Long Production Lead Times: Traditional methods like casting, milling, and manual adjustments often led to extended production cycles, taking up to several days for complex dental parts such as crowns, bridges, and implants.

Before integrating 3D printing into their workflow, Unique Dental Trading Corp faced significant challenges associated with traditional dental manufacturing methods:

High Costs: Outsourcing the manufacturing of intricate metal parts resulted in higher costs, including material wastage and transportation fees.

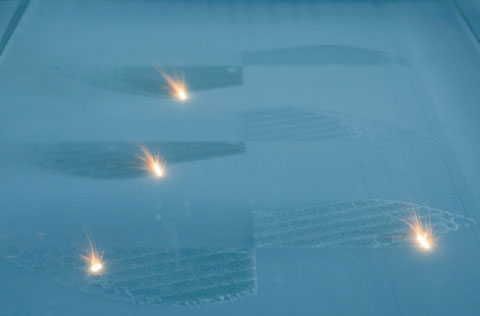

To overcome these challenges, Unique Dental Trading Corp turned to the LM-M100DLite metal 3D printer from Suzhou Linmu3D. This machine, designed specifically for dental applications, utilizes laser powder bed fusion technology and offers several advantages over traditional methods:

Build Volume: 100mm diameter × 50–80mm height, perfectly suited for dental parts.

Laser Power: 300W, ensuring high precision for dental components.

Material Compatibility: Supports titanium alloys, stainless steel, and cobalt-chromium alloys, commonly used for dental implants and crowns.

Layer Thickness: 20–60μm, allowing for highly detailed parts.

Design Flexibility: Unlike traditional methods, the LM-M100DLite allows for the creation of complex, customized dental parts with intricate details and unique designs without the need for expensive molds or manual labor.

Faster Production Times: The traditional process could take several days to produce a single dental component, but with the LM-M100DLite, production time has been reduced to 2-3 days.

Cost Savings: By bringing the production of complex dental parts in-house, the company reduced outsourcing costs by 30%, eliminating expenses associated with shipping, labor, and material waste.

Enhanced Customization: The LM-M100DLite’s advanced capabilities enabled the creation of highly personalized dental components, tailored to the specific needs of patients, without compromising quality or precision.

Increased Efficiency: The ability to print multiple parts simultaneously and with higher accuracy enabled Unique Dental Trading Corp to produce dental components in batch production.

Acetabular cup

Dentures

Tumor acetabular cup