- HOME

- CaseMedical Orthopedics

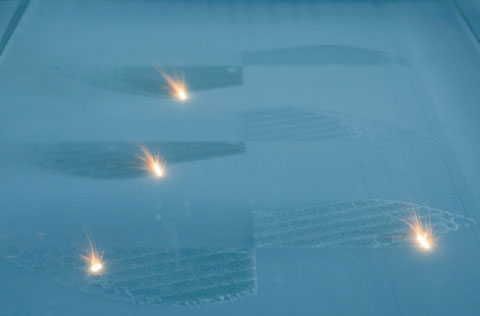

Stahanivets CAD CAM Center Improves Dental Manufacturing with LM-M100DLite Metal 3D Printer

Project:

Printing Service

Technology:

Metal 3D powder printing

Complated:

Summer 2019

Advanced Innovation Through Additive Manufacturing

Customer Profile

Stahanivets CAD CAM Center is a leading digital dental manufacturing facility in Ukraine, specializing in high-precision

CAD/CAM milling and 3D printing services for dental professionals. With over 16 years of experience, the center provides advanced digital solutions for creating customized dental restorations, including crowns, bridges, and implants.

“The LM-M100DLite has significantly streamlined our dental manufacturing process. We are now able to offer faster turnaround times and more precise, customized solutions for our clients.”

— Technical Director, Stahanivets CAD CAM Center

Long production lead times: Traditional processes for creating metal dental parts were time-consuming.

High outsourcing costs: Complex parts often had to be outsourced, leading to increased expenses.

Limited design flexibility: The traditional casting and milling process limited the ability to produce complex, customized dental components.

To address these issues, Stahanivets CAD CAM Center purchased the LM-M100DLite metal 3D printer from Suzhou Linmu3D. The LM-M100DLite is a compact desktop metal 3D printer designed for precise dental applications. Key features include:

Laser Power: 300W

Layer Thickness: 20–60 microns

Print Size: 100mm diameter, 50–80mm height

Materials Supported: Titanium alloys, stainless steel, cobalt-chromium alloy

Precision: High-precision printing suitable for intricate dental parts

Reduced lead times: Production times for custom dental parts were reduced from several days to just 2–3 days.

Cost savings: In-house production eliminated outsourcing costs, reducing overall production costs by 30%.

Enhanced design capabilities: The LM-M100DLite enabled the center to produce complex, customized parts that were previously difficult or expensive to manufacture.

Increased flexibility: The center was able to quickly iterate on designs and produce small batches of customized parts without the need for expensive molds or tooling.

Dentures

Dentures

Tumor acetabular cup